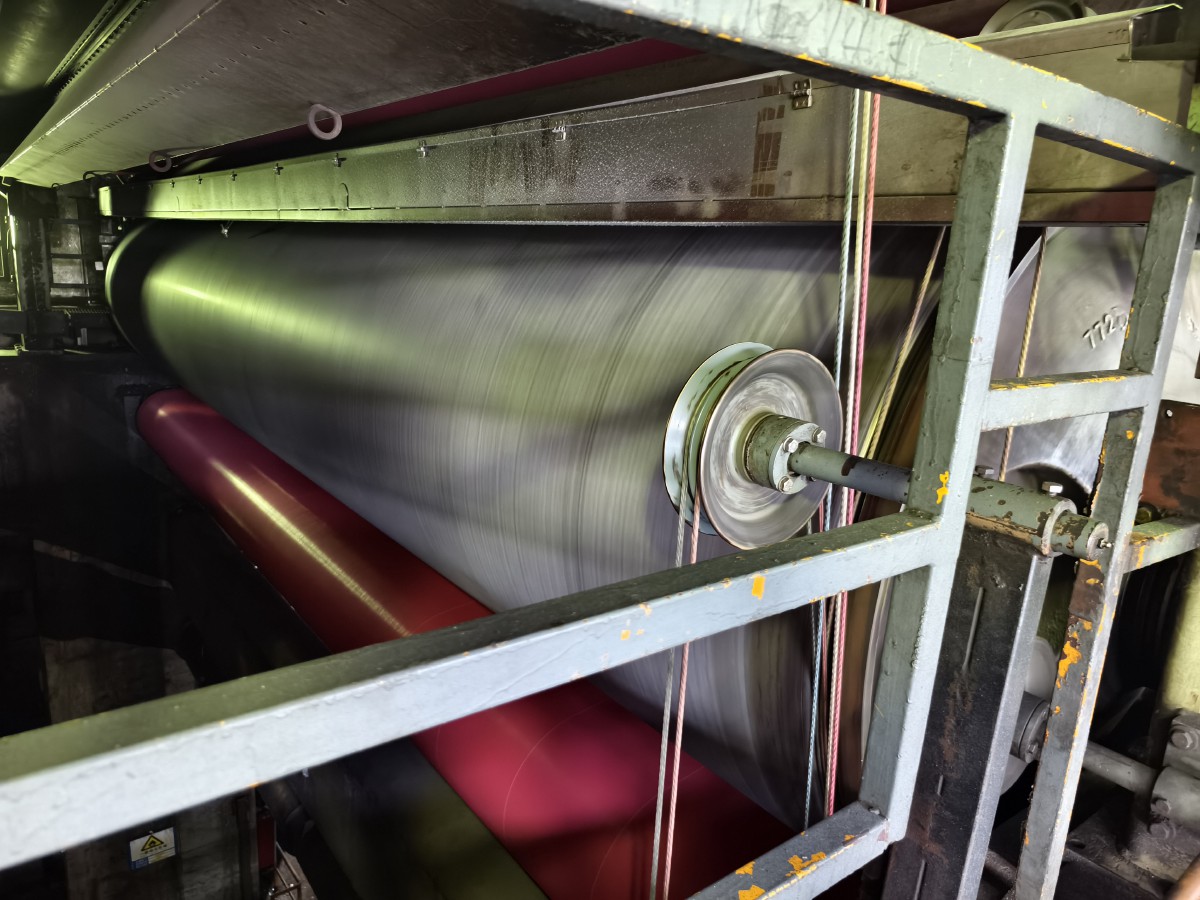

In the demanding world of paper manufacturing, achieving consistent quality and maximizing uptime are paramount. Yet, an insidious enemy constantly threatens these goals: sticky deposits and contaminants that build up on critical paper machine components like dryer cylinders and press felts. These “stickies” lead to frequent sheet breaks, reduced heat transfer efficiency, increased energy consumption, and costly downtime for cleaning.

Solving this persistent challenge requires more than just reactive measures; it demands a proactive, intelligent approach. That’s where a high-performance release agent spray system comes in. But with various options available, how do you determine what’s truly the best release agent spray system for your paper machine? This guide will break down the essential criteria, critical features, and a leading solution designed to transform your paper production.

Why Your Paper Machine Needs a Superior Release Agent Spray System

The modern paper industry, driven by increasingly stringent environmental regulations and the need for higher efficiency, often relies on closed-loop white water systems. While eco-friendly, this practice inadvertently concentrates stickies and other contaminants, exacerbating their negative impact.

Without an effective solution, your operation faces:

- Reduced Production Efficiency: Frequent sheet breaks due to stickies adhering to dryer cylinders, leading to unscheduled shutdowns and significant output losses.

- Compromised Product Quality: Contaminants transferring to the paper sheet, causing defects, spots, and reduced market value.

- Increased Maintenance & Operating Costs: Constant manual cleaning of equipment, higher energy consumption from inefficient heat transfer, and premature wear on components.

- Safety Hazards: Manual cleaning procedures in hot, confined spaces can pose risks to personnel.

A well-designed release agent spray system is not just an add-on; it’s an indispensable tool for maintaining continuous, high-quality, and cost-effective paper production. By creating a uniform protective layer on surfaces, it prevents adhesion, facilitates the release of paper, and actively manages stickies, ensuring smooth machine operation.

Key Factors Defining the “Best” Release Agent Spray System

To truly excel, a release agent spray system must go beyond basic functionality. It needs to address the unique complexities of paper manufacturing with precision, reliability, and intelligence. When evaluating the best system, consider these critical factors:

Precision and Uniformity of Application

The effectiveness of a release agent hinges on its even distribution. Inconsistent spraying leads to wasted chemicals, unprotected areas, and continued stickie issues. Look for systems with advanced atomization technology that ensures fine, uniform misting across the entire web width. This minimizes chemical consumption while maximizing surface coverage.

Reliability and Durability in Harsh Conditions

Paper machines operate in environments characterized by high temperatures, humidity, corrosive chemicals, and continuous vibration. A robust system must be constructed from materials that can withstand these extreme conditions without degradation, ensuring long-term stable operation and minimal component failure.

Intelligence and Automation

Manual intervention is inefficient and prone to error. The best systems integrate intelligent control, offering automation features like automatic start/stop, speed control, and smart interlocking with the paper machine’s signals. This reduces labor costs, optimizes performance, and ensures consistent application.

Ease of Maintenance and Serviceability

Downtime is costly. A superior system should be designed for quick and easy maintenance. Features like modular construction, accessible components, and self-cleaning capabilities significantly reduce the time and effort required for routine checks and repairs.

Customization and Adaptability

Every paper machine is unique, with varying widths, speeds, and specific contamination challenges. A “one-size-fits-all” approach rarely delivers optimal results. The best systems offer tailored solutions, allowing for customized installation, adjustable spray patterns, and flexible configurations to perfectly match your specific operational needs.

Proven Performance and Technical Expertise

Ultimately, the system must deliver measurable results. Look for providers with a strong track record, validated performance data, and a deep understanding of paper machine dynamics. Expertise in R&D, patent portfolios, and a dedicated technical support team are strong indicators of a reliable partner.

Introducing Jiangsu Baozhitong: Your Partner for Integrated Release Agent Spray Solutions

At Jiangsu Baozhitong Energy Saving Technology Co., Ltd., we believe that “customer trust” is the bedrock of our growth. As a high-tech enterprise specializing in integrated release agent spray system solutions for the paper industry, we’ve dedicated ourselves to overcoming the industry’s toughest challenges. With over 70% market share in China and trusted by more than 30 major paper groups, Baozhitong stands as a testament to our commitment to innovation, quality, and service.

Our corporate motto, “Paper Machine Release Agent Spray System Integrated Solution Provider,” reflects our holistic approach. We don’t just supply equipment; we provide comprehensive, custom-engineered solutions rooted in our core values: Independent R&D, Precise Spraying, Energy Saving & Consumption Reduction, and Stable & Reliable Performance.

Baozhitong Intelligent Release Agent Spray System: Features & Benefits That Deliver

The Baozhitong Intelligent Release Agent Spray System is engineered to directly address the industry pain points discussed, transforming your production line from a source of frustration into a beacon of efficiency.

Unmatched Efficiency and Stability

Our system is proven to significantly reduce stickies and improve overall machine performance.

- Dirt Reduction: Experience a remarkable 75% to 83% decrease in contaminant accumulation.

- Production Efficiency Boost: Witness an average 15% increase in overall production efficiency.

- Reduced Downtime: Cut down unscheduled cleaning stops by over 50%, drastically enhancing Overall Equipment Effectiveness (OEE).

By maintaining cleaner surfaces, we reduce sheet breaks, eliminate the need for frequent manual cleaning, and ensure a continuous, stable production flow.

Patented Precision Atomization

At the heart of our system lies our independently developed, patented secondary atomization nozzle. This innovative design ensures:

- Ultra-Fine Mist: Creates a finer, more uniform mist for optimal, consistent coverage.

- Targeted Application: Minimizes overspray and chemical waste, ensuring every drop counts.

- “Air Barrier” Design: Uniquely designed to resist interference from ambient airflow, maintaining spray integrity even in turbulent environments.

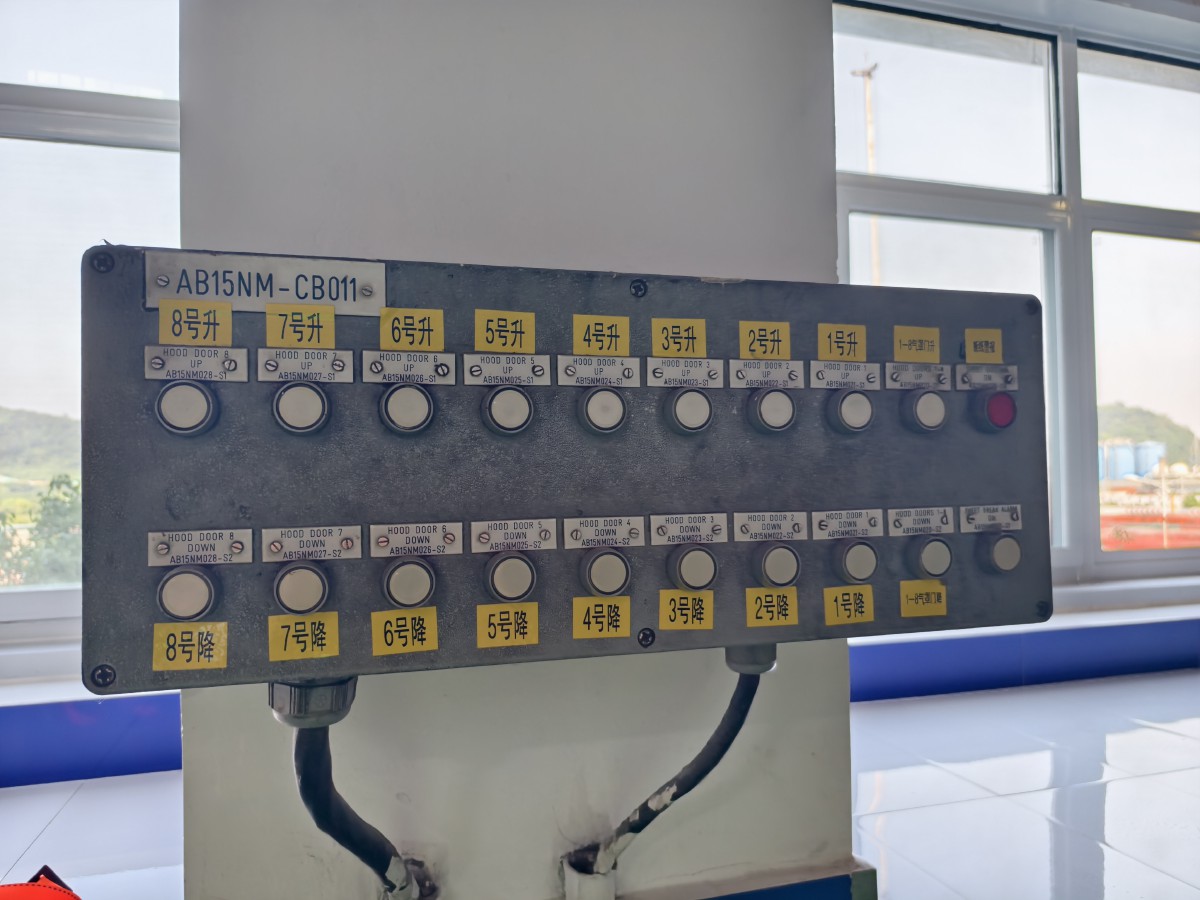

Advanced PLC Smart Control

The Baozhitong system features a sophisticated PLC intelligent control system, acting as the “brain” for seamless automation:

- Automated Interlocking: Intelligently links with production line signals (e.g., machine stop, sheet break) for automatic start/stop commands, requiring no manual intervention.

- DCS Integration: Seamlessly integrates with your Distributed Control System (DCS) for remote operation, monitoring, and data exchange, fostering a truly smart factory environment.

- Energy-Saving Strategies: The metering pump automatically stops when the main unit pauses, preventing agent waste and further reducing operational costs.

- Precise Dynamic Execution: Variable frequency drive (VFD) for stepless speed regulation and adjustable limit switches allow for micro-adjustment of spray speed and range.

Robust Design for Extreme Environments

Built to endure, our system ensures longevity and reliability in the most challenging paper machine conditions:

- Premium Materials: The machine body is constructed from 304 stainless steel, offering exceptional corrosion resistance.

- High-Temperature Resistance: Core pipelines, made from Teflon (PTFE), withstand temperatures up to 240°C. Key components like limit switches are specifically chosen for their high-temperature tolerance.

- Japanese Imported Motors: Provide powerful, stable operation even in hot and humid conditions.

User-Friendly & Low Maintenance

Designed for convenience and minimal operational burden:

- Easy Access for Maintenance: Innovative structural design allows the main body to be easily pulled out from its slot for swift inspection and maintenance.

- Automated Self-Cleaning: New automatic spot-cleaning functions keep nozzles clear and maintain optimal performance without manual effort.

- Daily Operation Freedom: Once configured, the system operates autonomously, freeing up operator time.

Tailored Solutions for Every Machine

We understand that customization is key to success:

- “One Factory, One Policy” Customization: We provide bespoke solutions tailored to your specific site conditions and paper machine configuration.

- Flexible Spray Head Configurations: Supports single, dual, or triple spray head setups, with adjustable directions to perfectly match various paper web widths. Our patented “adjustable range spraying device” dynamically matches different paper widths, eliminating waste.

Core Components Ensuring Peak Performance

Every part of the Baozhitong system is chosen for its quality and function:

- Proprietary Secondary Atomization Nozzle: Engineered for ultimate atomization and even coverage.

- Imported Metering Pump: Ensures precise and adjustable flow rates for accurate release agent dosage.

- High-Temperature Limit Switches: Guarantee stable operation in challenging environments.

- Pump Station: Comprises imported metering pumps and flow calibration columns for accurate agent supply.

- Control Cabinet: The central control unit, managing power, spray head movement, pump operation, and DCS integration.

The Baozhitong Difference: Expertise, Experience, Authority, Trust

Choosing the best release agent spray system means partnering with a company that embodies E-E-A-T (Expertise, Experience, Authority, and Trust). Baozhitong stands out in every aspect:

A Legacy of Innovation and Growth

From our founding in 2013 to our current position as a national high-tech enterprise, our journey has been marked by relentless innovation. In 2022, our new generation spray system launched to widespread market acclaim, and by 2024, our domestic market share exceeded 70%. We hold over 60 national patents, with more than 20 core patents integrated directly into our products, including our highly reliable “automatic reversing spraying device.”

Industry-Leading Technical Team

Our core strength lies in our people. With over 40 employees, including 2 PhDs and 4 Master’s degree holders, our technical staff comprises over 50% of our workforce. This deep bench of expertise drives our continuous R&D and ensures our solutions are at the cutting edge.

Proven Track Record with Industry Giants

Trust is built through results. We are proud to have established long-term, stable partnerships with numerous top paper groups both domestically and internationally. Our esteemed partners include:

- Lee & Man Paper

- Nine Dragons Paper

- Shanying International

- APP Sinar Mas Group

- Sun Paper

- Bohui Paper

- Gold Hongye Paper

- Golden Phoenix Paper

- Jianhui Paper

- Rong Sheng Environment

- Hupo Paper

- Solenis (Chemical Partner)

- And many other prominent names like Yuantong Paper, Rongsheng Paper, Shunyu Paper, Huayu Paper.

Tangible Results for Our Clients

Our commitment to excellence translates into significant, measurable benefits for our customers:

- Cost Reduction: Approximately 30% reduction in operational costs.

- Output Increase: Approximately 25% increase in paper production.

- Paper Quality Improvement: Approximately 30% enhancement in paper quality.

Comprehensive Service and Support

Your success is our priority. We provide end-to-end support including professional on-site installation guidance, detailed maintenance manuals, and readily available remote and on-site technical assistance, ensuring peace of mind throughout your system’s lifespan.

Common Questions About Release Agent Spray Systems

Understanding the practicalities of operating and maintaining a release agent spray system is crucial. Here are some frequently asked questions:

Q1: What if a single limit switch fails? A: In case of a single limit switch failure, you can access the emergency operation interface. Select the failed side and set a single-trip running time. This allows for temporary continued production. Always ensure to perform maintenance and repair the switch promptly after the production run.

Q2: What should I do if the spray head’s atomization effect is poor? A: Poor atomization is typically caused by a clogged spray head. Immediately replace it with a spare spray head to restore production. Afterwards, clean or repair the clogged spray head. Regular inspection and cleaning can prevent this issue.

Q3: Which parts should I always have as spares? A: Essential wear parts to keep on hand include spray heads, drag chains, limit switches, relays, and gas/liquid pipes. Regular inspection of these components is recommended, and having spares ensures minimal downtime during replacement.

Q4: Why is the green light on the control cabinet continuously illuminated? A: A continuously illuminated green light on the control cabinet could indicate several issues: an input interlocking signal, the motor speed setting is too low, a circuit fault, or a loose chain. Please check these possibilities systematically based on your specific site conditions.

Choosing the right release agent spray system is a strategic investment that directly impacts your paper machine’s efficiency, product quality, and profitability. By focusing on precision, reliability, automation, and proven expertise, you can make an informed decision that drives long-term success.

Ready to optimize your paper production and eliminate stickie challenges?

Contact Jiangsu Baozhitong Energy Saving Technology Co., Ltd. today to discover how our intelligent release agent spray system can be custom-engineered to deliver exceptional results for your paper machine. Experience the Baozhitong difference—where innovation meets efficiency.