In the demanding world of papermaking, unscheduled downtime is the enemy of profitability. Contaminants, stickies, and pulp residues accumulating on dryer cylinders and fabrics are a primary cause of paper breaks, forcing costly production halts for manual cleaning. While release agents offer a solution, their application method is the difference between wasting resources and achieving a new level of operational excellence.

Traditional, manually-adjusted, or non-integrated spray systems often fall short. They can be imprecise, wasteful, and unable to adapt to dynamic production conditions. This is where a PLC (Programmable Logic Controller) controlled release agent spray system becomes a game-changing investment. By integrating intelligent automation into the core of the application process, these systems offer a cascade of benefits that directly impact your bottom line.

Let’s explore the seven core advantages that make this technology essential for any modern paper mill.

The Core Benefits of a PLC-Integrated Spray System

1. Drastically Reduced Machine Contamination (75-83% Reduction)

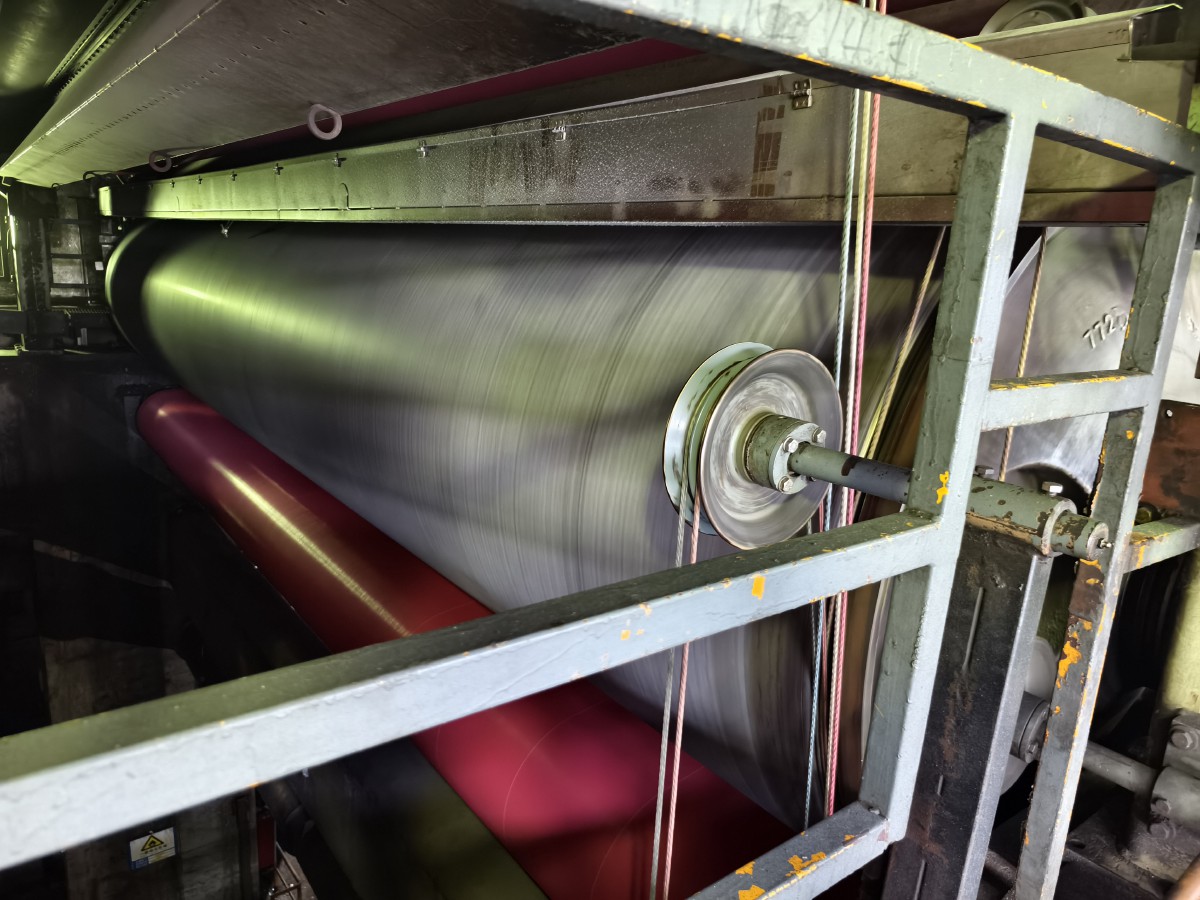

The fundamental goal is a cleaner machine, and a PLC-controlled system delivers this with unparalleled effectiveness. By using patented, precision-engineered atomizing nozzles, the system lays down a micro-thin, perfectly uniform protective film across the entire surface of the dryer cylinder or fabric.

This isn’t just a crude spray; it’s a precisely metered and targeted application that:

- Proactively Prevents Adhesion: It stops stickies and other contaminants from gaining a foothold in the first place.

- Dissolves Existing Buildup: The active agents in the coating work to dissolve and strip away any previously formed deposits.

The result? A proven contamination reduction rate of 75% to 83%, keeping your critical surfaces cleaner for longer.

2. Significant Decrease in Paper Breaks and Downtime

Contaminant buildup creates an uneven surface, leading to weak spots in the paper sheet and causing frequent, frustrating paper breaks. Furthermore, the accumulation eventually necessitates a complete shutdown for cleaning.

A PLC-controlled system directly tackles this by:

- Maintaining a Smooth Surface: A consistently clean cylinder or fabric ensures a stable, uniform paper sheet, directly reducing the frequency of breaks.

- Eliminating Unscheduled Cleaning Stops: By preventing the problem from developing, the need for emergency cleaning downtime is drastically reduced—often by over 50%. This transforms lost time back into valuable production hours.

3. Superior Precision and Chemical Savings

Waste is a hidden cost in many mills. Overspraying release agents not only costs money in wasted chemicals but can also create an aerosol fog in the facility. PLC systems introduce surgical precision.

- Intelligent Dosing: The system’s imported electromagnetic metering pump, controlled by the PLC, dispenses the exact amount of release agent required—no more, no less.

- Targeted Application: With adjustable traversing speeds and limit switches, the spray coverage can be perfectly matched to the paper web width. If you’re running a narrower sheet, the system adjusts automatically, preventing overspray onto exposed machine parts.

- Advanced Atomization: Patented nozzles create an exceptionally fine mist that provides complete coverage with minimal chemical volume, eliminating drips and waste.

4. Enhanced Energy Efficiency

Clean machine components run more efficiently. This is a simple law of physics that a PLC spray system leverages for significant energy savings.

- Improved Heat Transfer: A clean dryer cylinder transfers heat to the paper sheet far more effectively than one coated in insulating contaminants. This allows you to achieve the same drying effect with lower steam consumption.

- Reduced Drive Load: Sticky buildup increases the drag on fabrics and rolls, forcing drive motors to work harder and consume more electricity. A clean, low-friction surface reduces this load, saving energy.

5. Full Automation & “Set-and-Forget” Operation

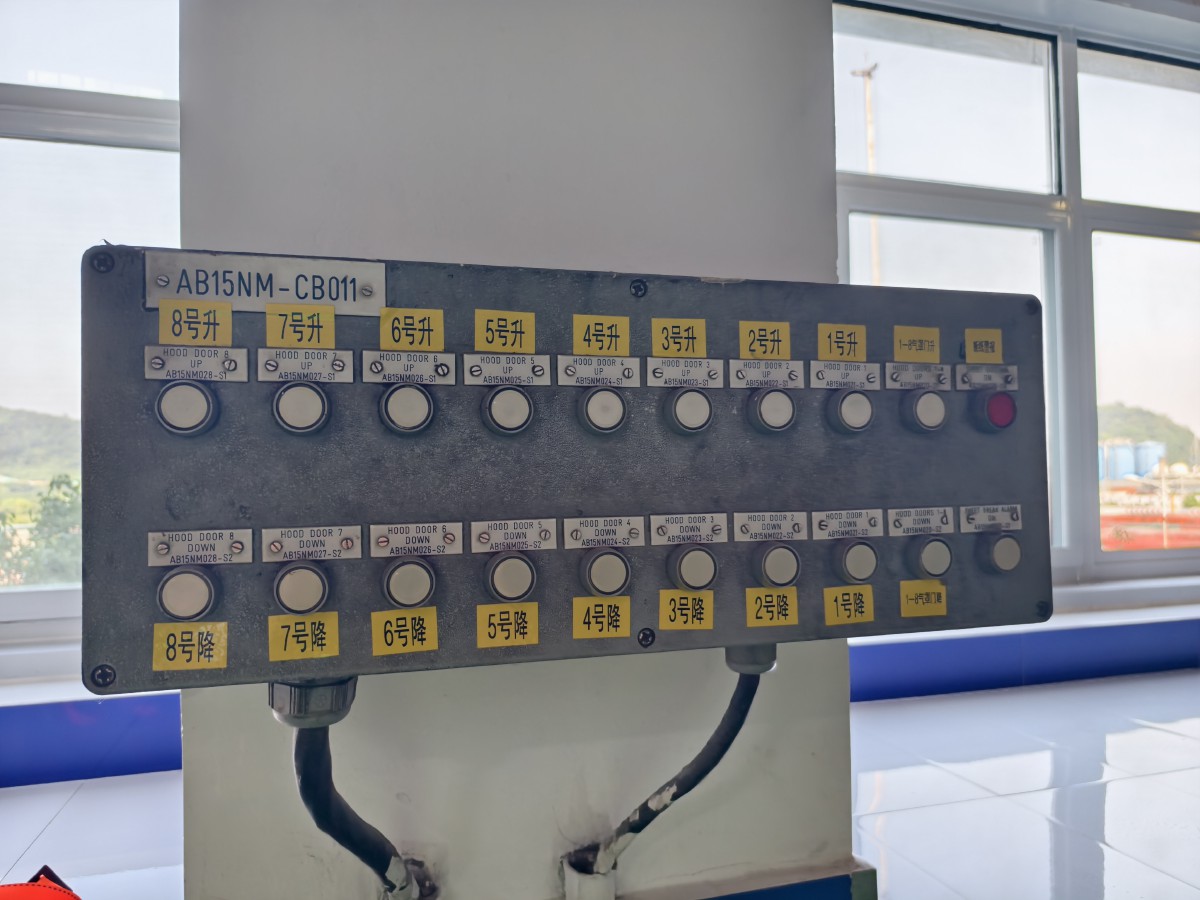

The “PLC” is the brain of the operation, enabling true, unattended automation that integrates seamlessly with your production line. This eliminates the risk of human error and frees up your operators for more critical tasks.

- Smart Interlocking: The system automatically links to key machine signals. It starts when the line runs, pauses during a paper break, and stops during a planned shutdown. The metering pump only runs when needed, preventing any waste.

- DCS Integration: The system can be fully integrated with your plant’s Distributed Control System (DCS), allowing for remote start/stop control and status monitoring from the central control room.

6. Improved and More Consistent Paper Quality

Machine contamination is a direct cause of defects like spots, holes, and uneven coating, leading to rejected reels and customer complaints. By ensuring a pristine machine environment, a PLC-controlled system helps you produce a higher quality, more consistent final product, boosting its market value and your reputation. This can lead to a direct improvement in final paper quality by around 30%.

7. Durability and Reliability in Harsh Environments

Paper mills are hot, humid, and corrosive environments. A system not built to withstand these conditions will fail. A top-tier PLC-controlled system is engineered for longevity. Key components are selected for their resilience, including:

- 304 Stainless Steel Construction: For maximum corrosion resistance.

- High-Temperature Components: Withstanding up to 240°C, from Teflon tubing to specialized limit switches and drive motors.

- Robust Design: Ensuring stable, repeatable performance day in and day out, shift after shift.

The Baozt Solution: Where Intelligent Design Meets Proven Performance

Understanding these benefits is the first step. The next is finding a system engineered to deliver them reliably in the harshest mill environments. This is where the Baozt Intelligent Release Agent Spray System sets a new standard. As an integrated solution provider for the papermaking industry, Baozt has engineered a system that embodies every one of these advantages.

Our system is not just a collection of parts; it’s a comprehensive solution born from deep industry expertise and a commitment to innovation.

Key Features of the Baozt System:

- Patented Dual-Atomization Nozzles: Our proprietary nozzles create an ultra-fine, targeted mist. A unique “air barrier” design shields the spray from ambient air currents, ensuring the release agent lands precisely where it’s needed, drastically reducing chemical fog and waste.

- True “Set-and-Forget” Smart Integration: Our PLC system intelligently interlocks with all critical machine signals (stop, paper break, etc.) for fully autonomous operation. With DCS remote control, it becomes a seamless part of your smart factory network.

- Engineered for the Harshest Conditions: We use 304 stainless steel for the main body and high-temperature-rated components (up to 240°C) for all critical parts, from the Japanese-made drive motor to the Teflon piping and limit switches.

- Designed for Easy Maintenance: An innovative slide-out design allows the entire main assembly to be pulled out from its housing on a tray, making inspection and maintenance quick, safe, and simple.

Trusted by Industry Leaders

With over 70% market share in the domestic market, Baozt is the trusted partner for giants of the paper industry, including Lee & Man Paper, Nine Dragons Paper, APP Sinar Mas Group, and Sun Paper. Our technology is validated by multiple national patents and an ISO9001:2015 certification, but our greatest pride is the tangible results we deliver to our partners:

- Production Efficiency: Increased by up to 15%

- Cleaning Downtime: Reduced by over 50%

- Overall Costs: Reduced by approximately 30%

Frequently Asked Questions (FAQ)

Q: What happens if a limit switch fails during operation? A: Our system is designed with a failsafe. You can switch to an emergency operation mode via the control interface, setting a single-pass run time to maintain production temporarily. We strongly recommend servicing the switch at the next scheduled stop.

Q: What should I do if the nozzle atomization seems poor? A: This is typically caused by a blockage. The first step is to swap in a spare nozzle to immediately restore production. You can then clean or service the blocked nozzle offline.

Q: Which spare parts should we keep on hand? A: We recommend stocking common wear parts such as nozzles, drag chains, limit switches, relays, and air/chemical tubing to ensure maximum uptime.

Move From Reactive Cleaning to Proactive Control

Stop letting machine contamination dictate your production schedule. The move to a PLC controlled release agent spray system is a strategic shift from reactive, costly cleaning to proactive, automated contamination control. It’s an investment that pays for itself through increased uptime, reduced costs, and higher quality output.

If you are ready to unlock a new level of efficiency and reliability in your paper mill, the next step is simple.

Contact the Baozhitong team today for a customized assessment of your production line and discover how our intelligent spray system can transform your operations.