In the demanding world of papermaking, operational efficiency and product quality are paramount. However, a persistent foe – contaminants and “stickies” – constantly threatens to disrupt production, leading to frustrating downtime, reduced sheet quality, and increased costs. Papermaking release agent spraying emerges as a critical weapon in this battle, offering a proactive solution to maintain clean surfaces and ensure seamless operation.

This comprehensive guide delves into the essence of papermaking release agent spraying, exploring its vital role, the science behind effective application, and how cutting-edge technology is transforming the industry.

Understanding the Necessity of Release Agents in Papermaking

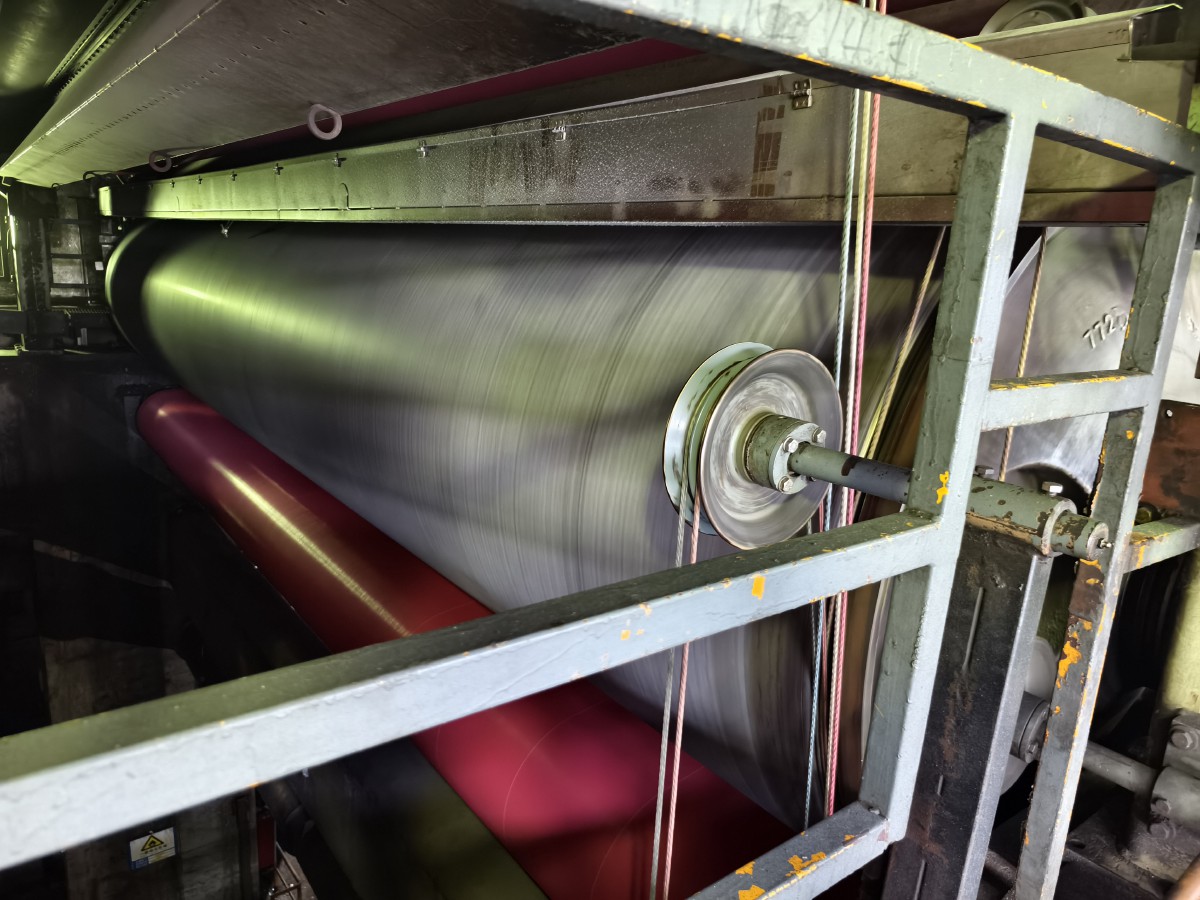

The modern papermaking process, with its emphasis on closed-loop white water systems for environmental compliance and water conservation, inadvertently intensifies the problem of stickies. These sticky contaminants, originating from various sources like recycled fibers, coatings, and sizing agents, accumulate on critical paper machine surfaces such as dryer cylinders, press rolls, and fabrics.

This accumulation leads to a cascade of negative effects:

- Increased Sheet Breaks: Stickies cause the paper web to adhere to machine surfaces, leading to frequent and often unpredictable breaks.

- Reduced Product Quality: Contaminant transfer to the paper sheet results in spots, holes, and uneven surfaces, significantly impacting the final product’s appearance and strength.

- Decreased Machine Efficiency (OEE): Frequent cleaning cycles and longer downtimes for maintenance drastically lower overall equipment effectiveness.

- Higher Energy Consumption: A dirty dryer cylinder surface has poor heat transfer efficiency, requiring more steam to dry the paper.

- Shorter Felt and Fabric Life: Abrasion and fouling from stickies can prematurely wear out expensive machine clothing.

Papermaking release agents are specially formulated chemical solutions designed to create a non-stick barrier on these surfaces, preventing adherence and facilitating easy release of the paper web. They either dissolve existing build-up or create a protective layer that repels new contaminants.

The Art and Science of Effective Release Agent Spraying

Simply applying a release agent isn’t enough; how it’s applied is critical to its effectiveness. Spraying is the preferred method, offering precision, uniformity, and continuous protection.

Key elements of effective release agent spraying include:

1. Nozzle Technology and Atomization

The heart of any spraying system is its nozzle. For release agents, achieving a fine, consistent mist (atomization) is crucial. This ensures even coverage across the entire width of the paper web or dryer surface. Poor atomization leads to uneven application, creating unprotected areas where stickies can still accumulate, or over-application in other areas, wasting costly chemicals.

2. Precise Dosing and Flow Control

Applying the correct amount of release agent is vital. Under-dosing renders the treatment ineffective, while over-dosing wastes chemicals and can potentially introduce other issues. A robust system employs highly accurate metering pumps to control the flow rate precisely, allowing for adjustments based on paper grade, machine speed, and contamination levels.

3. Strategic Application Points

Release agents are typically sprayed onto surfaces where stickies are most problematic. Common application points include:

- Dryer Cylinders: To prevent sticking and maintain heat transfer efficiency.

- Press Felts and Rolls: To reduce picking and extend felt life.

- Forming Wires: In some cases, to prevent early build-up.

The system must be designed to withstand the harsh conditions (high heat, humidity, chemicals) prevalent at these points.

4. Uniform Coverage and Oscillation

To prevent striping or gaps in protection, the spraying system needs to ensure uniform coverage across the entire width of the machine. This often involves an oscillating spray bar that moves back and forth, distributing the agent evenly. The speed and range of this oscillation are critical adjustments.

5. Automation and Integration

Modern papermaking demands intelligent systems. An effective release agent spraying solution integrates seamlessly with the paper machine’s control system (DCS or PLC). This allows for automatic adjustments, interlocks with machine status (e.g., stopping when the machine stops to prevent waste), and remote monitoring.

Overcoming Common Challenges in Release Agent Application

Traditional or poorly designed spraying systems often encounter several hurdles:

- Uneven Application: Leads to localized fouling and wasted chemicals.

- Nozzle Clogging: Impairs spray patterns and requires frequent manual cleaning.

- Chemical Wastage: Due to overspray, dripping, or inefficient atomization.

- System Downtime: For maintenance, cleaning, or repairs in harsh environments.

- Environmental Concerns: Airborne mist or chemical runoff if not contained properly.

- Difficulty in Maintenance: Complex designs make servicing time-consuming and labor-intensive.

These challenges highlight the need for specialized, robust, and intelligent solutions that move beyond basic spraying setups.

Elevating Papermaking Efficiency with Advanced Spraying Solutions

While the principles of release agent spraying are clear, achieving optimal, sustainable results demands advanced engineering and smart design. This is where specialized solutions, like those offered by Jiangsu Baozhitong Energy Saving Technology Co., Ltd. (Baozhitong), transform the landscape.

Baozhitong is a high-tech enterprise dedicated to providing integrated release agent spraying system solutions for the papermaking industry. Our motto, “Papermaking Release Agent Spraying System Integrated Solution Provider,” reflects our commitment to addressing the core pain points of modern paper mills.

Our systems are engineered to counteract the challenges of stickies and dramatically enhance production efficiency. By deploying high-precision atomized release agents, a uniform protective coating is formed on dryer cylinders or dry mesh surfaces. This layer not only effectively dissolves and strips away existing contaminants but also actively prevents new ones from adhering, tackling the root cause of production issues.

Baozhitong’s Core Advantages: Precision, Reliability, and Intelligence

Drawing on over a decade of dedicated innovation and an R&D team comprising PhDs and postgraduates, Baozhitong’s intelligent release agent spraying systems offer a distinct set of advantages:

- Patented Dual-Atomization Nozzles: Our independently developed, patented nozzles achieve extremely fine and dense mist droplets, ensuring precise and uniform coverage. A unique “air barrier” design actively resists site airflow interference, minimizing agent splash and wastage.

- PLC Intelligent Interlocking & Automation: The system integrates advanced PLC control, automatically interlocking with production line signals such as machine stops or sheet breaks. It supports DCS remote start/stop control, enabling fully automated, unattended operation, and significantly reducing human intervention.

- Robust & Durable Construction: Built for the harshest papermaking environments, our machine bodies are constructed from 304 stainless steel. Core pipelines are made of high-temperature-resistant Teflon (up to 240°C), and critical components like limit switches are selected for their resilience to high temperatures and humidity.

- Significant Efficiency Gains: Our proven technology delivers tangible results:

- Contaminant Reduction: 75% – 83% decrease in sticky buildup.

- Production Efficiency Boost: Approximately 15% increase.

- Reduced Cleaning Downtime: Over 50% fewer planned and unplanned shutdowns for cleaning.

- Energy Savings: Cleaner roller surfaces mean higher heat transfer efficiency and lower steam consumption.

- Convenient and Worry-Free Maintenance: An innovative structural design allows the equipment body to be easily pulled out from its trough for inspection. Daily operation requires no manual intervention, complemented by a new automatic spot cleaning function.

- “One Plant, One Policy” Customization: We understand that every paper machine is unique. Baozhitong provides tailored solutions that ensure perfect integration with your specific site conditions and production requirements.

- Unrivaled Technical Strength & Market Leadership: With over 60 patents (20+ core patents applied), certifications as a “National High-Tech Enterprise,” and a track record of serving over 30 major paper groups (including industry giants like Lee & Man Paper, Nine Dragons Paper, APP Sinar Mas Group, and Sun Paper), Baozhitong commands over 70% of the domestic market share.

Implementing a Smart Release Agent Spraying System: What to Look For

When considering an advanced release agent spraying system, look for providers that prioritize:

- Precision & Efficiency: Does the system promise exact dosing and uniform coverage without waste?

- Automation & Intelligence: Can it integrate with your existing control systems and operate autonomously?

- Durability & Reliability: Is it built with high-quality, corrosion-resistant, and heat-resistant materials for long-term stability?

- Ease of Maintenance: Does the design facilitate quick and easy servicing to minimize downtime?

- Customization: Can the system be tailored to your specific machine geometry and operational needs?

- Proven Track Record & Support: Does the provider have a strong reputation, verified performance data, and robust after-sales service?

Baozhitong’s commitment to these principles ensures that your investment translates into tangible improvements in your papermaking operations.

Frequently Asked Questions about Release Agent Spraying

Here are answers to common queries regarding release agent spraying systems:

Q1: What should I do if a single limit switch malfunctions? A: Access the emergency operation interface, select the side that has failed, and set a single-stroke running time to maintain temporary production. Be sure to inspect and repair it promptly during the next planned shutdown.

Q2: My spray nozzle’s atomization effect is poor. What’s the cause? A: This is usually due to a clogged nozzle. Replace it with a spare nozzle immediately to restore production, then clean or repair the clogged nozzle.

Q3: Which spare parts should I keep on hand? A: Commonly recommended spare parts include spray nozzles, drag chains, limit switches, relays, and air/liquid pipes. Regular inspection and having these spares ready are advisable.

Q4: The control cabinet’s green light remains on. What could be the reason? A: Possible causes include a constant interlock signal input, the motor speed setting being too low, a circuit fault, or a loose chain. Please troubleshoot these possibilities based on your specific site conditions.

Q5: How quickly can I expect to see results after installing a Baozhitong system? A: The effects are immediate. You will notice a significant reduction in dirt and stickies, leading to fewer sheet breaks and a smoother production process very quickly. Our data shows a 75-83% reduction in dirt accumulation from day one.

Conclusion

Effective papermaking release agent spraying is no longer a luxury but a fundamental requirement for optimizing paper machine performance, ensuring product quality, and achieving sustainable operations. By understanding the critical role of precision, automation, and robust design, paper mills can transform their approach to contamination control.

Baozhitong stands as your trusted partner, providing not just equipment, but an integrated, intelligent, and highly reliable solution built on deep expertise and proven results. Our commitment to innovation, energy efficiency, and environmental responsibility, combined with our unparalleled market experience, positions us to help you overcome your toughest papermaking challenges.

Ready to achieve unparalleled efficiency and quality in your papermaking process? Contact Baozhitong today for a customized intelligent release agent spraying system solution tailored to your needs.