For paper manufacturers, achieving consistent quality and maximizing output are paramount. Yet, an insidious enemy often lurks within the production line: paper machine fouling. This stubborn buildup of deposits not only compromises product quality but also leads to frequent, costly shutdowns, eating away at profits and productivity.

This comprehensive guide delves into the root causes of paper machine fouling, explores its devastating impact, and, crucially, unveils advanced strategies to eliminate paper machine fouling and reduce downtime, paving the way for a more efficient and profitable operation.

The Silent Saboteur: Understanding Paper Machine Fouling

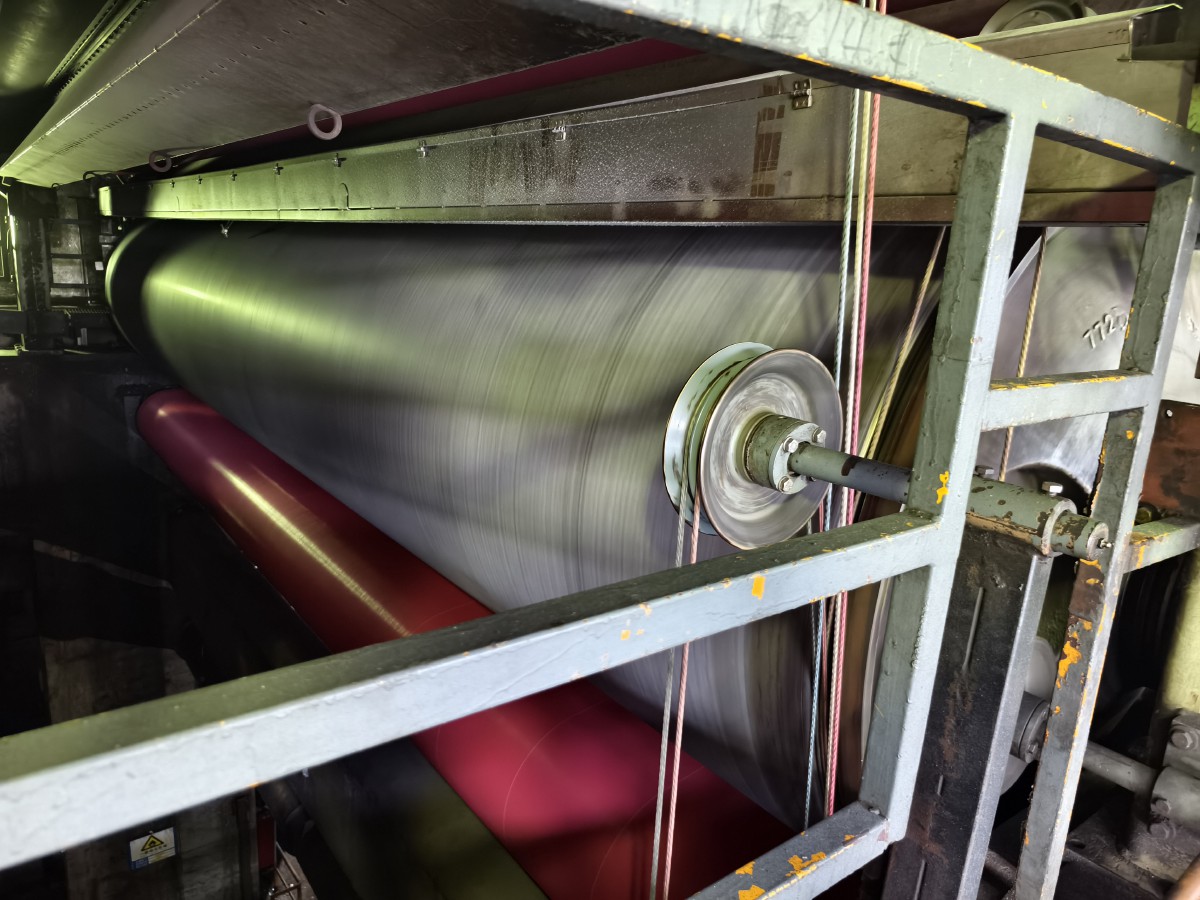

Paper machine fouling refers to the accumulation of unwanted material—such as pitch, stickies, mineral deposits, and biological slime—on critical components of the paper machine. From wires and felts to press rolls, dryer cans, and even pulping equipment, these deposits can adhere to virtually any surface, disrupting the delicate balance of the papermaking process.

What Exactly is Fouling?

Fouling isn’t a single substance but a complex mix. It can manifest as:

- Stickies: Residues from adhesives, coatings, and binders, particularly prevalent with recycled fiber.

- Pitch: Natural resins extracted from wood pulp, which can agglomerate and deposit.

- Mineral Scale: Hard deposits formed by the precipitation of calcium carbonate, silicates, or other inorganic compounds.

- Biological Slime: Biofilms formed by bacteria, fungi, and algae thriving in warm, moist conditions.

- Fiber and Filler Buildup: Small fibers and inorganic fillers that can become entangled and adhere to surfaces, especially in conjunction with stickies or pitch.

The Ripple Effect: Why Fouling is a Major Problem

The consequences of paper machine fouling extend far beyond a dirty surface. Its presence creates a cascade of operational nightmares:

- Reduced Production Efficiency: Fouling leads to frequent sheet breaks, forcing operators to slow down the machine or stop it entirely for cleaning. This directly impacts overall equipment effectiveness (OEE).

- Compromised Product Quality: Deposits can transfer to the paper sheet, causing blemishes, holes, or inconsistent caliper, leading to rejected product batches.

- Increased Maintenance Costs: Regular, often unplanned, cleaning requires significant labor, chemicals, and downtime. This also accelerates wear and tear on components, shortening their lifespan.

- Higher Energy Consumption: Fouled dryer cans lose heat transfer efficiency, demanding more steam to dry the paper, thus increasing energy costs.

- Environmental Concerns: Traditional harsh chemical cleaning methods can generate problematic wastewater, increasing environmental burden.

- Safety Hazards: Manual cleaning procedures often expose workers to hazardous conditions and chemicals.

Understanding these profound impacts underscores the urgency of effective fouling elimination strategies.

Root Causes of Fouling: Pinpointing the Culprits

To effectively eliminate paper machine fouling, one must first identify its origins. The problem is rarely singular; often, a combination of factors contributes to deposit formation.

White Water System Closure

Modern paper mills increasingly operate with closed-loop white water systems to conserve water and reduce effluent. While environmentally beneficial, this practice concentrates dissolved and colloidal substances (DCS), making them more prone to deposition. These concentrated contaminants are a primary driver for increased fouling.

Chemical Interactions & Stickies

The complex chemistry within a paper machine can inadvertently promote fouling. Additives, sizing agents, and even residual inks from recycled pulp can interact to form sticky, hydrophobic particles. Furthermore, the increasing use of recycled fibers introduces a significant amount of “stickies” from adhesives and plastics, which readily deposit on machine surfaces.

Microbial Growth

Paper machines provide an ideal environment—warm, wet, and nutrient-rich—for microorganisms to flourish. Bacteria, fungi, and algae can form robust biofilms (slime) that not only cause fouling but also create a matrix for other deposits to adhere to.

Fiber and Filler Buildup

Even clean fibers and fillers can contribute to fouling. When combined with other sticky substances, or if machine surfaces are rough, these materials can agglomerate and build up, creating a foundation for more severe deposits.

Traditional Approaches: Managing Fouling, Minimizing Downtime

For decades, paper mills have employed various methods to combat fouling. While offering some relief, these approaches often present their own set of challenges.

Mechanical Cleaning

- High-Pressure Washing: Manual or automated systems use water jets to remove deposits during shutdowns. Effective for immediate removal but cannot prevent future buildup.

- Scrapers and Doctor Blades: Continuously remove deposits from rolls and dryer cans. Can be effective but require careful setup and maintenance to avoid damaging surfaces.

Chemical Treatment Programs

- Dispersants: Chemicals designed to keep particles suspended in the furnish, preventing them from depositing.

- Biocides: Used to control microbial growth and prevent slime formation.

- Release Agents: Applied to surfaces to reduce the adhesion of deposits.

- Wash-Up Chemicals: Strong chemicals used during scheduled shutdowns for thorough cleaning.

Operational Adjustments

- Optimizing Retention Aids: Proper retention can help minimize fiber and filler losses that contribute to fouling.

- Careful pH Control: Maintaining optimal pH levels can reduce the solubility of certain contaminants and prevent their deposition.

- Regular Wire and Felt Cleaning: Ensures these critical components remain open and free of buildup.

Limitations of Conventional Methods

While these methods can manage fouling, they often fall short of truly eliminating paper machine fouling and reducing downtime significantly:

- Reactive, Not Proactive: Many methods address fouling after it has occurred, leading to inevitable production interruptions.

- Inconsistent Effectiveness: Manual cleaning varies in thoroughness, and chemical treatments can be challenging to optimize for dynamic mill conditions.

- High Costs: Labor, chemicals, water, and lost production hours due to downtime accumulate rapidly.

- Environmental Impact: Aggressive chemical usage can be detrimental.

- Risk of Damage: Mechanical scraping or high-pressure washing can potentially damage delicate machine surfaces.

Clearly, a more advanced, proactive, and integrated solution is needed to overcome these persistent challenges.

Beyond Band-Aids: A Proactive & Integrated Solution

The future of paper production demands a shift from reactive problem-solving to proactive prevention. This is where cutting-edge intelligent spraying systems emerge as a game-changer for eliminating paper machine fouling and reducing downtime at its source.

These systems apply specialized release agents or anti-fouling chemicals directly and continuously to critical machine surfaces, creating a protective barrier that prevents deposits from adhering in the first place.

Jiangsu Baozhitong: Revolutionizing Paper Production with Smart Spraying

Jiangsu Baozhitong Energy Saving Technology Co., Ltd. (Baozt) stands at the forefront of this revolution. As an “Integrated Solution Provider for Paper Machine Fouling Inhibitor Spraying Systems,” Baozt understands the paper industry’s stringent demands for stability and efficiency. Our mission, rooted in “customer trust,” is to deliver high-tech, energy-saving, stable, and reliable solutions.

We believe in “Independent R&D | Precise Spraying | Energy Saving | Stable & Reliable” as our core values, driving our commitment to innovation and excellence.

The Baozt Advantage: Precision, Efficiency, Reliability

Baozt’s intelligent spraying system is engineered to thrive in the harshest paper machine environments. Designed with high-temperature and corrosion-resistant materials, our equipment ensures long-term stable operation where others fail. Our technical prowess, backed by a team including PhDs and postgraduates, and over 60 national patents (with 20+ core patents), allows us to deliver solutions that are not just effective but transformative.

With a market share exceeding 70% in China, Baozt is the trusted partner for over 30 major paper groups.

How Baozt’s System Tackles Fouling Head-On

Our intelligent release agent spraying system is specifically designed to combat the challenges arising from increasingly closed white water systems and the resultant severe paper machine fouling. It works by:

- High-Precision Atomization: Our patented secondary atomizing nozzles create extremely fine, uniform mist droplets of release agent.

- Even Coating: This mist is precisely applied to critical surfaces like dryer cans or dry felts, forming a consistent protective film.

- Proactive Prevention: This coating actively prevents new pollutants from adhering to the surface.

- Active Removal: It also effectively dissolves and peels off any existing deposits, from the source.

This dual action directly addresses the root causes of fouling, keeping your machine consistently clean and operational.

Key Benefits: Transformative Results for Your Mill

Implementing Baozt’s intelligent spraying system delivers quantifiable improvements that directly impact your bottom line:

- Eliminate Paper Breaks: By preventing deposit buildup, our system drastically reduces the frequency of sheet breaks, leading to higher finished product yield.

- Drastically Reduce Cleaning Downtime: Say goodbye to frequent, unplanned shutdowns for cleaning. Our system reduces cleaning-related downtime by over 50%, boosting your Overall Equipment Effectiveness (OEE).

- Lower Operating Energy Consumption: A clean roll surface ensures superior heat transfer efficiency, leading to a significant reduction in steam consumption. Reduced machine load also contributes to overall energy savings.

- Enhanced Production Efficiency: With a 75% – 83% reduction in fouling and consistently clean surfaces, mills experience an average production efficiency increase of approximately 15%.

- Improved Paper Quality: Reduced fouling means fewer imperfections on the paper, leading to a 30% improvement in paper quality.

- Cost Savings: Our clients often report a 30% reduction in overall operating costs.

Unpacking the Technology: What Makes Baozt Stand Out?

Our system’s six core advantages highlight our commitment to “Technical Innovation | Energy Efficiency | Green Environmental Protection | Cooperative Win-Win”:

- Efficient & Stable (Significant Enhancement): Over 75% fouling reduction, significantly fewer paper breaks and shutdowns, leading to comprehensive production efficiency improvements.

- Precise Spraying (Patented Technology): Patented secondary atomizing nozzles create finer droplets and more precise, uniform application. A unique “air barrier” design effectively counteracts on-site airflow interference, minimizing agent splash and waste.

- Smart Operation (Automatic Control): Integrated PLC intelligent control system automatically interlocks with production line signals (e.g., shutdown, sheet break) and supports DCS remote start/stop, enabling unattended smart operation. Our system’s six intelligent functions include precise dynamic execution, efficient energy-saving strategies, modular task nozzles, autonomous interlocking, intelligent state sensing, and collaborative control.

- Convenient & Easy Maintenance: Innovative structural design allows the main equipment body to be easily pulled out from its trough for inspection. Daily operation requires no manual intervention, and a new automatic fixed-point cleaning function is included.

- Durable (Harsh Condition Design): The main body is constructed from 304 stainless steel, core pipelines are made of high-temperature resistant Teflon (up to 240°C), and critical components like limit switches are selected for their high-temperature endurance, ensuring reliability in severe conditions.

- Service Guarantee (Worry-Free After-Sales): We provide professional on-site installation guidance, detailed maintenance manuals, and readily available remote and on-site technical support to ensure seamless operation.

The system’s robust components, including Japan-imported motors, imported electromagnetic metering pumps, and high-temperature limit switches, are meticulously chosen for their performance and longevity.

Real-World Impact: Proven Success with Industry Leaders

Baozt’s commitment to excellence and proven results has earned us the trust of major players in the paper industry. Our partnerships with leading paper groups are a testament to our solutions’ effectiveness.

Testimonials Through Partnerships

We have established long-term, stable, and mutually beneficial relationships with industry giants such as:

- Lee & Man Paper

- Nine Dragons Paper

- Shanying International

- APP Sinar Mas Group

- Sun Paper

- Bohui Paper

- Gold Hongye Paper

- Golden Phoenix Paper

- Jianhui Paper

- Rong Sheng Environment

- Hupo Paper

- Solenis (chemical partner)

- And many more prominent enterprises like Yuantong Paper, Rongcheng Paper, Shunyu Paper, Huayu Paper.

These partnerships underscore our reputation for reliability and the tangible value we deliver.

Quantifiable Improvements

Our clients consistently achieve impressive results:

- Cost Reduction: Approximately 30%

- Yield Increase: Approximately 25%

- Paper Quality Improvement: Approximately 30%

These statistics aren’t just numbers; they represent increased profitability, sustainable operations, and a significant competitive advantage for our partners.

Your Questions Answered: Common Concerns About Fouling & Spraying Systems

We understand that implementing new technology comes with questions. Here are answers to some common concerns:

Q1: What if a single limit switch fails?

A: Our system provides an emergency operation interface. You can select the failed side and set a single-trip running time to ensure temporary production continuity. However, it’s crucial to inspect and repair the switch promptly during the next planned shutdown.

Q2: What if the spray nozzle’s atomization effect is poor?

A: This is typically caused by nozzle clogging. We recommend immediately replacing it with a spare nozzle to restore production. The clogged nozzle can then be cleaned or repaired offline.

Q3: Which parts are considered common wear and tear items that should be kept in stock?

A: Common consumables include spray nozzles, drag chains, limit switches, relays, and air/liquid tubes. We advise regular inspection and maintaining a sufficient supply of these spare parts.

Q4: Why is the control cabinet’s green light constantly on?

A: This could indicate several issues: a locking signal input, motor speed set too low, a circuit fault, or a loose chain. Please troubleshoot these possibilities based on your specific on-site conditions. Our comprehensive service and support team is always ready to assist with diagnostics and solutions.

The Future of Paper Production: Stability, Efficiency, Profitability

Paper machine fouling is a formidable challenge, but it is not insurmountable. By embracing advanced, integrated solutions like the Baozt Intelligent Release Agent Spraying System, paper mills can move beyond reactive maintenance to proactive prevention. This strategic shift leads to a dramatic reduction in downtime, significant improvements in production efficiency and product quality, and substantial cost savings.

The future of papermaking is clean, stable, and highly profitable.

Ready to Transform Your Paper Mill?

Stop battling relentless fouling and the costly cycle of downtime. Discover how Jiangsu Baozhitong’s proven technology can deliver unparalleled stability, efficiency, and profitability to your operation.

Contact us today for a customized solution tailored to your unique paper machine and production needs. Let us help you eliminate paper machine fouling and reduce downtime for good.