The modern papermaking industry faces relentless pressure: optimize output, cut costs, meet stringent environmental standards, and maintain impeccable product quality. For decades, one persistent challenge has been the accumulation of “stickies” on dryer cylinders and felts. These sticky deposits lead to frustrating paper breaks, frequent downtime for cleaning, and compromised paper quality. While release agents offer a solution, traditional application methods often fall short, introducing inconsistencies and waste.

This is where fully automatic release agent spraying steps in – not just as an improvement, but as a paradigm shift, heralding a new era of efficiency, reliability, and precision in papermaking. It’s the essential innovation driving the industry forward.

The Imperative for Automation in Papermaking

In a world demanding higher production speeds and continuous operation, manual or semi-automatic interventions are no longer sustainable. The drive towards closed-loop white water systems, while environmentally beneficial, intensifies the problem of stickies by concentrating contaminants. This necessitates a more sophisticated, consistent, and proactive approach to managing deposits. Automation is no longer a luxury; it’s a strategic necessity to overcome these complex operational hurdles and secure a competitive edge.

What is Release Agent Spraying and Why Does It Matter?

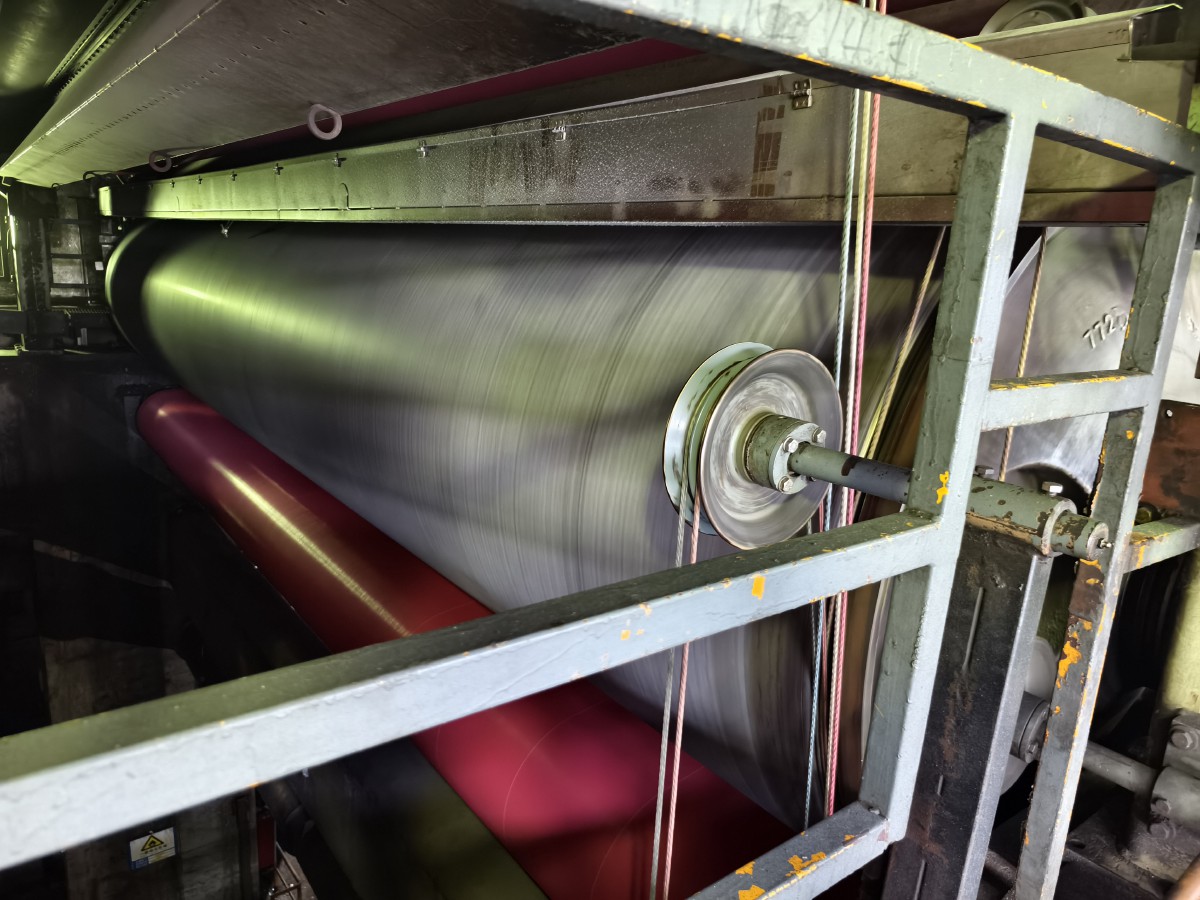

Release agents are specialized chemicals designed to prevent pulp fibers and contaminants from adhering to critical paper machine surfaces, particularly dryer cylinders and dry felts. By forming a protective, non-stick layer, they facilitate smooth paper web release and prevent the buildup of sticky substances. Effective application is crucial: inconsistent spraying can lead to uneven protection, localized buildup, and continued operational issues. This is precisely where the “fully automatic” aspect becomes revolutionary.

Transforming Papermaking: The Power of Fully Automatic Systems

A fully automatic release agent spraying system represents a leap forward from its predecessors. It eliminates the inconsistencies of manual application, ensuring a precisely controlled and uniform coating across the entire target surface. This level of automation means:

- Unwavering Consistency: Every inch of the dryer surface receives the optimal amount of release agent, eliminating hot spots and under-protected areas.

- Continuous Operation: The system operates seamlessly, integrated with the production line, preventing the need for manual intervention and associated shutdowns.

- Data-Driven Optimization: Smart controls allow for fine-tuning based on real-time production data, ensuring maximum effectiveness with minimal agent consumption.

- Enhanced Safety: Removing personnel from hazardous, high-temperature zones during application significantly improves workplace safety.

Core Benefits of Advanced Automatic Spraying

Embracing fully automatic release agent spraying delivers a cascade of benefits that directly impact a paper mill’s bottom line and operational stability:

- Dramatic Reduction in Paper Breaks: Consistent application prevents sticky buildup, which is a primary cause of web breaks. This directly translates to higher finished product yield.

- Significant Decrease in Cleaning Downtime: By preventing fouling, the need for frequent, time-consuming manual cleaning of dryer sections is drastically reduced, boosting Overall Equipment Effectiveness (OEE).

- Lower Running Costs: Precise, optimized spraying minimizes release agent consumption, while cleaner rolls lead to better heat transfer, reducing steam consumption and lowering energy bills.

- Improved Paper Quality: A clean, uniformly coated surface ensures consistent paper properties, reducing defects and improving the final product’s appearance and performance.

- Extended Equipment Lifespan: Reduced abrasive cleaning and consistent surface protection minimize wear and tear on expensive dryer cylinders and felts.

- Greater Operational Stability: With fewer unexpected disruptions, production runs smoother, more predictably, and with greater control.

How Smart Systems Deliver Uninterrupted Performance

The effectiveness of a fully automatic system lies in its sophisticated integration of mechanical precision, intelligent control, and robust materials. These systems typically comprise:

- Precision Spray Heads: Designed to atomize the release agent into ultra-fine droplets, ensuring uniform coverage with minimal waste.

- Intelligent Control Units: Often PLC-based, these systems monitor production line signals, automatically adjust spray parameters, and can integrate with plant-wide Distributed Control Systems (DCS).

- Durable Transport Mechanisms: Robust linear motion systems or oscillating spray bars ensure precise and repeatable spray head movement.

- High-End Materials: Components exposed to heat, moisture, and chemicals are constructed from corrosion-resistant and high-temperature tolerant materials, guaranteeing longevity in harsh mill environments.

The synergy of these components allows for dynamic adjustment of spray patterns and volumes based on paper width, machine speed, and even specific production recipes, truly elevating the concept of automated efficiency.

Baozt’s Fully Automatic Release Agent Spraying System: A Deep Dive into Innovation

Among the pioneers driving this transformative shift is Jiangsu Baozhitong Energy Saving Technology Co., Ltd. (Baozt). With a robust background as a high-tech enterprise and commanding over 70% market share in China, Baozt is synonymous with innovation and reliability in providing integrated solutions for papermaking release agent spraying systems. Leveraging years of dedicated research and development, Baozt’s intelligent spraying system directly addresses the industry’s most pressing pain points, offering a future-proof solution.

Precision Engineering for Unmatched Performance

Baozt’s system embodies its core values of independent R&D, precise spraying, energy saving, and stable reliability. Its design and features are tailored for the demanding papermaking environment:

- Proprietary Secondary Atomization Nozzles: At the heart of the system are Baozt’s patented spray nozzles. These innovative designs achieve an ultra-fine mist, ensuring precise and uniform coating. A unique “gas barrier” mechanism effectively counters ambient airflow interference, preventing drift and ensuring every drop of agent lands where it’s needed, minimizing waste.

- Robust & Resilient Design: Built for extreme conditions, the main body is constructed from durable 304 stainless steel. Core pipelines are made from Teflon (PTFE), rated to withstand temperatures up to 240°C. Critical components like limit switches are chosen specifically for their high-temperature resistance, guaranteeing stable operation in humid, hot environments. Japanese imported motors provide powerful and reliable motion, even under constant stress.

- Smart PLC Integration for Intelligent Control: The system is powered by an advanced PLC intelligent control unit, capable of seamless interlocking with production line signals such as machine stops or paper breaks. This allows for fully automatic start/stop operations without manual intervention. Furthermore, it supports DCS remote start/stop control, integrating effortlessly into modern smart factory networks.

- User-Centric Maintainability: Recognizing the importance of uptime, Baozt’s innovative structural design allows the equipment body to be easily pulled out from its tray for quick and convenient inspection or maintenance. Daily operation requires no human intervention, and a new automatic fixed-point cleaning function further simplifies upkeep.

- Customized Solutions (“One Factory, One Policy”): Understanding that no two paper mills are identical, Baozt offers bespoke solutions. Each system is customized to perfectly match the specific site conditions and production requirements, ensuring optimal integration and performance from day one.

Tangible Results: Data-Driven Success

The impact of Baozt’s Fully Automatic Release Agent Spraying System is not just theoretical; it’s proven with quantifiable results from over 30 major paper groups:

- Dirty Reduction Rate: A staggering 75% to 83% decrease in sticky accumulation.

- Production Efficiency Boost: An average 15% increase in overall production efficiency.

- Cleaning Downtime Reduction: Over 50% fewer planned and unplanned shutdowns for cleaning.

- Overall Cost Reduction: Approximately 30% lower operational costs due to reduced agent waste and energy savings.

- Paper Quality Improvement: Approximately 30% enhancement in paper quality attributes.

These figures underscore Baozt’s commitment to delivering high-performance, cost-effective, and environmentally responsible solutions. The company holds over 60 national patents, with more than 20 core patents successfully applied to its products, including “adjustable range spraying devices” and “automatic reversing spraying devices,” which further enhance efficiency and reliability. Baozt is also ISO9001:2015 certified and recognized as a National High-Tech Enterprise.

Addressing Your Operational Concerns: Baozt’s Expert Support

Implementing new technology can bring questions, and Baozt stands ready with comprehensive support. Here are answers to some common inquiries:

- Q1: What if a single limit switch fails? A: In such an event, an emergency operation interface allows you to select the affected side and set a single-stroke running time, ensuring temporary production continuity. It is crucial to perform maintenance promptly during the next planned shutdown.

- Q2: My spray head’s atomization effect is poor. What should I do? A: This usually indicates a clogged spray head. We recommend replacing it with a spare immediately to resume production. The clogged spray head can then be cleaned or repaired offline.

- Q3: What are the essential wear parts I should stock? A: Key wear parts include spray heads, drag chains, limit switches, relays, and gas/liquid pipes. Regular inspection and maintaining a stock of these spares are highly recommended for uninterrupted operation.

- Q4: The control cabinet’s green light remains on. What could be the cause? A: This could stem from several issues: an active interlocking signal input, an overly low motor speed setting, a circuit fault, or a loose chain. Please systematically check these possibilities based on your on-site conditions.

Baozt provides professional on-site installation guidance, detailed maintenance manuals, and readily available remote and on-site technical support to ensure seamless operation and peace of mind for its partners, including industry giants like Lee & Man Paper, Nine Dragons Paper, Sinar Mas Group (APP), and many others.

The Future is Now: Partnering for Papermaking Excellence

The era of fully automatic release agent spraying has arrived, and it’s fundamentally reshaping the papermaking landscape. By eliminating bottlenecks, enhancing efficiency, and significantly reducing operational costs, this advanced technology empowers mills to meet the demands of tomorrow. Jiangsu Baozhitong Energy Saving Technology Co., Ltd. is leading this charge, offering a proven, intelligent, and reliable solution that ensures cleaner machines, smoother production, and a more sustainable future for the industry.

Ready to transform your papermaking operations, achieve unprecedented levels of efficiency, and secure your place in the future of the industry?

Contact Jiangsu Baozhitong Energy Saving Technology Co., Ltd. today to discuss a customized automatic release agent spraying solution tailored for your mill.