The rhythmic hum of a paper machine is the sound of productivity, yet hidden beneath its powerful operations lies a pervasive threat: fouling. This relentless build-up of stickies, fibers, and chemicals on dryer rolls and felts is a silent saboteur, quietly eroding efficiency, increasing costs, and compromising product quality. For years, the papermaking industry has grappled with this challenge, seeking solutions that move beyond temporary fixes to deliver sustained, flawless production.

This article delves into the core of papermaking fouling, explores its impact, and unveils how advanced spray systems are transforming operations. Crucially, we’ll uncover what it means to partner with a specialist who understands the journey from constant struggle to unwavering operational excellence.

The Costly Truth: Understanding Papermaking Fouling and Its Impact

In the pursuit of environmental sustainability and resource efficiency, modern papermaking processes increasingly rely on closed-loop white water systems. While beneficial for the planet, this practice intensifies the concentration of dissolved and colloidal substances, leading to a surge in deposits on critical machine components. These “stickies” and other contaminants accumulate, forming stubborn layers that wreak havoc on production.

The consequences are far-reaching and financially significant:

- Frequent Paper Breaks: Fouling creates uneven surfaces, leading to sheet sticking and an increased frequency of costly paper breaks. Each break means lost production, wasted raw materials, and stressed operators.

- Unscheduled Downtime for Cleaning: To maintain even a semblance of efficiency, machines must be stopped for manual cleaning – a labor-intensive, time-consuming process that directly impacts overall equipment effectiveness (OEE).

- Reduced Heat Transfer Efficiency: Deposits on dryer cylinders act as insulation, demanding more steam and energy to achieve the desired drying effect, escalating operational costs.

- Compromised Product Quality: Uneven drying, surface imperfections, and potential contamination from detached deposits can degrade the quality of the final paper product, leading to customer complaints and reduced market value.

- Increased Chemical Consumption: Operators often over-apply chemicals in a desperate attempt to mitigate fouling, leading to higher material costs without necessarily solving the root problem.

The cumulative effect is a cycle of inefficiency, high operational costs, and constant frustration. The industry needs a shift from reactive cleaning to proactive prevention.

Beyond Band-Aids: The Strategic Shift to Proactive Spray Systems

Traditional methods of combating fouling – from manual scraping to high-pressure water jets – are reactive, disruptive, and often inadequate. They address the symptom, not the underlying process instability. Modern papermaking demands a more sophisticated approach: intelligent peeling agent spray systems designed for continuous, preventative action.

An effective papermaking spray system isn’t just about applying chemicals; it’s about precision, control, and integration. It aims to create a uniform, non-stick surface that prevents contaminants from adhering in the first place, or gently removes them as they form. This proactive strategy maintains machine cleanliness, optimizes efficiency, and ensures consistent product quality, moving operations from fouling to flawless.

Key benefits of adopting such a system include:

- Consistent Cleanliness: Continuous application keeps critical surfaces clean, preventing the build-up that leads to major problems.

- Reduced Reliance on Manual Labor: Automation minimizes the need for dangerous and tedious manual cleaning.

- Optimized Chemical Usage: Precise application ensures chemicals are used effectively, reducing waste and cost.

- Enhanced Machine Longevity: Preventing abrasive fouling reduces wear and tear on components.

Elevating Efficiency: Partnering for Papermaking Spray System Excellence

While the benefits of a robust spray system are clear, achieving true “flawless” production requires more than just equipment. It demands a partnership with an expert provider who understands the intricacies of papermaking, the science of adhesion, and the engineering of reliable, intelligent solutions.

Jiangsu Baozhitong Energy Saving Technology Co., Ltd. (Baozt) embodies this commitment. As a high-tech enterprise specializing in integrated peeling agent spray system solutions for the papermaking industry, Baozt has become a trusted name for over 70% of domestic paper manufacturers. Our foundation is built on “customer trust,” fueled by independent research and development, precise spraying technology, energy efficiency, and unwavering reliability.

Baozt’s journey began in 2013, focusing on energy-saving, automated, and environmentally friendly equipment. By 2020, our innovative capabilities earned us recognition as a “National High-Tech Enterprise.” Today, with over 60 patents (20+ core patents applied to products), including innovative adjustable range and automatic reversing spray devices, Baozt stands at the forefront of papermaking spray technology. Our team, with over 50% technical staff including PhDs and postgraduates, ensures that every solution is grounded in scientific excellence and practical experience.

We understand the demanding conditions of a paper machine – high temperatures, corrosive environments, and continuous operation. That’s why our products and services are engineered for:

- Harsh Environment Design: Equipment built with high-temperature, corrosion-resistant materials for long-term stability.

- Rapid Response Service: Modular, user-friendly design for easy maintenance, minimizing downtime.

- PLC Smart Interlock: Fully automated operation, seamlessly linked with production line signals, eliminating manual intervention.

- Tailored Solutions: Customized plans for every client, ensuring perfect integration with site conditions.

- Patented Atomizing Nozzles: Proprietary nozzles for precise, uniform application, preventing chemical waste.

- Verifiable Performance Data: Tangible results in reducing fouling, backed by measurable data.

Baozt’s Intelligent Peeling Agent Spray System: A Deep Dive into Flawless Production

The increasing demands for environmental protection and water conservation have exacerbated paper machine fouling, making it a critical bottleneck for production efficiency and product quality. Baozt’s Intelligent Peeling Agent Spray System is engineered precisely to address this challenge head-on.

By atomizing and precisely applying a peeling agent onto dryer cylinders or dry felts, our system forms a uniform protective coating. This coating not only effectively dissolves and removes existing deposits but also proactively prevents new contaminants from adhering. The result is a fundamental shift from reactive cleaning to preventative maintenance, delivering significant benefits:

- Resolving Paper Breaks: Our system demonstrably reduces paper break frequency caused by fouling, directly increasing finished product yield.

- Minimizing Downtime for Cleaning: Drastically cuts down on unscheduled stoppages for cleaning, reducing labor and material costs, and boosting Overall Equipment Efficiency (OEE).

- Lowering Operational Energy Consumption: Clean roller surfaces ensure superior heat transfer efficiency, leading to reduced steam consumption and overall energy savings.

Our key performance data speaks for itself:

- Fouling Reduction: 75% to 83%

- Production Efficiency Increase: Approximately 15%

- Cleaning Downtime Reduction: Over 50%

Imagine a scenario where dirty accumulation, frequent downtime, high paper break rates, and uncontrolled energy consumption are replaced by consistently clean surfaces, continuous stable production, and verifiable energy savings. This is the transformation Baozt delivers.

Six Core Advantages of Baozt’s System

Baozt’s spray system is engineered for efficiency, intelligence, and reliability:

- Highly Efficient & Stable (Significant Enhancement): Achieve over 75% reduction in fouling, significantly cutting down paper breaks and downtime, leading to a comprehensive boost in production efficiency.

- Precision Spraying (Specialized Technology): Our patented secondary atomization nozzles produce finer droplets and more precise application. The unique “air barrier” design effectively counters on-site airflow interference, minimizing chemical splash and waste.

- Intelligent Operation (Automatic Control): Integrated PLC intelligent control system automatically interlocks with production line signals (e.g., machine stops, paper breaks) and supports DCS remote start/stop control for unattended smart operation.

- Convenient & Hassle-Free (Easy Maintenance): Innovative structural design allows the main equipment body to be easily pulled out from its tray for inspection. Daily operation requires no manual intervention, complemented by a new automatic fixed-point cleaning function.

- Durable & Resilient (Rigorous Design): The machine body is constructed from 304 stainless steel, core pipelines are rated for up to 240°C, and critical components like limit switches are high-temperature resistant, ensuring robust performance in harsh conditions.

- Service Assurance (Worry-Free After-Sales): We provide professional on-site installation guidance, detailed maintenance manuals, and continuous remote technical support or on-site assistance, ensuring peace of mind for our customers.

System Composition and Component Detail

Baozt’s spray system is a sophisticated integration of mechanical, electrical, and automation technologies, meticulously designed for precision and reliability:

- Equipment Casing & Main Body: The casing protects internal components, while the main body is the core actuator, driving the spray head’s reciprocating motion.

- Pump Station: Featuring an imported metering pump and flow calibration column, it precisely delivers the required flow and pressure of the atomized peeling agent.

- Air Source: Utilizes the factory’s existing compressed air system to provide stable power for chemical atomization.

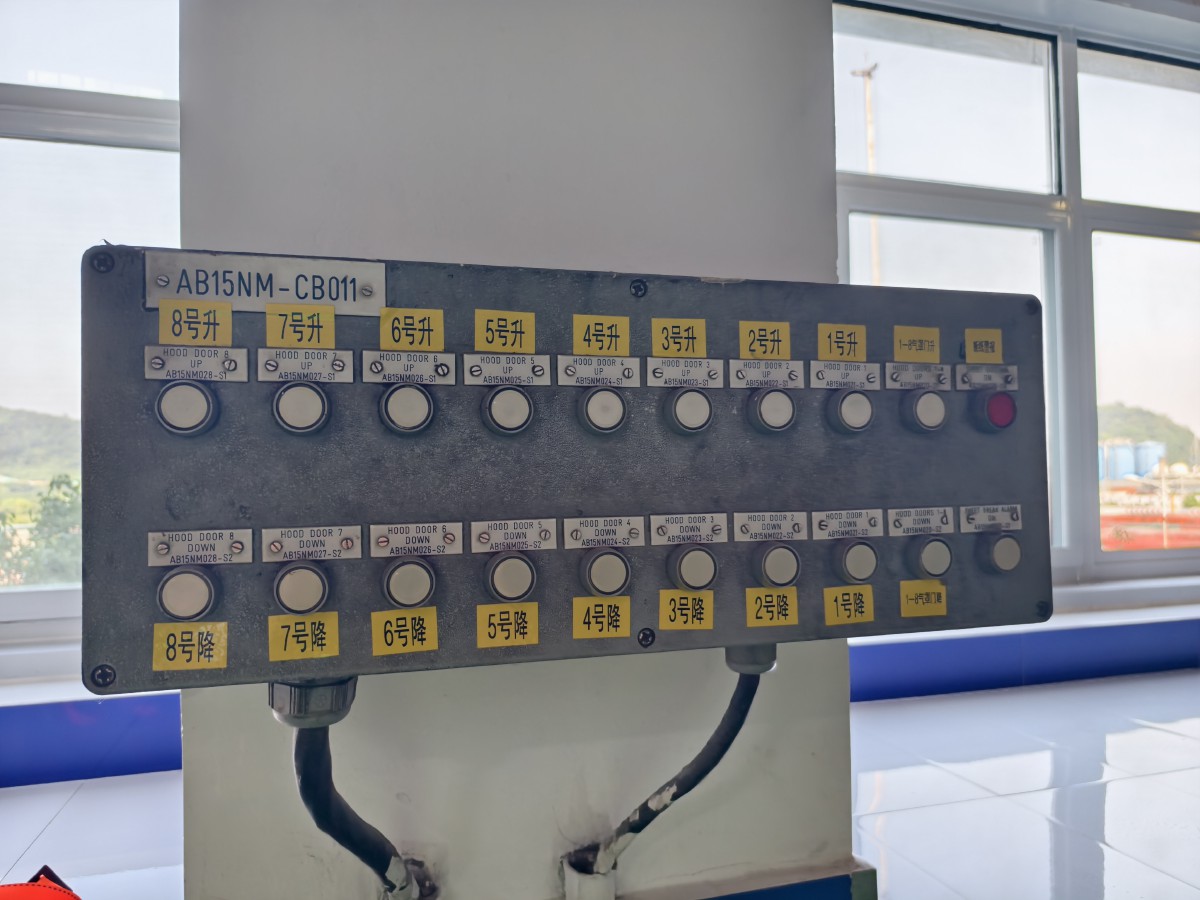

- Control Cabinet: The “brain” of the system, responsible for power supply, controlling spray head movement and speed, metering pump activation, and providing DCS remote interfaces.

- Air/Liquid Pipelines: All critical lines are made from high-temperature resistant (up to 240°C) Teflon (PTFE) material, ensuring stable and safe media transport.

- Mounting Brackets: Custom-designed based on site conditions (dryer or felt section) to securely fix the main equipment onto the production line.

Core Components Highlights:

- Patented Secondary Atomization Nozzle: Precision internal structure for ultimate atomization and uniform coverage.

- Imported Japanese Motor: Powerful, resistant to high temperature and humidity, ensuring stable operation.

- Imported Electromagnetic Metering Pump: Precisely adjustable flow for accurate chemical dosage control.

- High-Temperature Limit Switch: Reliable operation even in humid, high-temperature environments.

Fully Automatic Smart Spraying Functions

Our system integrates six intelligent functions, achieving truly autonomous operation:

- Precise Dynamic Execution: Variable frequency drive provides stepless speed adjustment and movable limit switches allow for precise fine-tuning of spraying speed and range.

- Efficient Energy-Saving Strategy: Intelligent interlock design automatically stops the metering pump when the main machine halts or the system pauses, eliminating waste.

- Modular Task Nozzles: Adjustable nozzle direction supporting single, dual, or triple nozzle configurations, flexibly adapting to different paper widths.

- Autonomous Decision-Making Interlock: Links with production line stop and paper break signals, automatically executing start/stop commands for unattended operation.

- Intelligent Status Sensing: Real-time monitoring of motor and spray head travel, with built-in timeout protection logic, automatically shutting down the system in case of abnormalities.

- Collaborative Control Network: Seamless integration with DCS systems, enabling remote control and status monitoring, embedding the system within your factory’s intelligent production network.

Proven Excellence: Baozt’s Track Record & Trust

Baozt’s dedication to innovation is recognized through numerous national utility model and invention patents, particularly for our “adjustable range spray device” and “automatic reversing spray device,” ensuring reliability and resource efficiency. We are ISO9001:2015 certified by NQA and proudly hold the title of National High-Tech Enterprise.

Our solutions consistently deliver impressive results for our clients:

- Cost Reduction: Approximately 30%

- Yield Increase: Approximately 25%

- Paper Quality Improvement: Approximately 30%

Industry-Leading Partnerships

Our long-standing, mutually beneficial partnerships with leading paper groups are a testament to our reliability and superior performance. Our esteemed partners include:

- Lee & Man Paper

- Nine Dragons Paper

- Shanying International

- APP Sinar Mas Group

- Sun Paper

- Bohui Paper

- Gold Hongye Paper

- Golden Phoenix Paper

- Jianhui Paper

- Rong Sheng Environment

- Hupo Paper

- Solenis

- …and many other renowned industry players like Yuantong Paper, Rongcheng Paper, Shunyu Paper, Huayu Paper.

Your Questions Answered: FAQs for Seamless Operation

We believe in empowering our partners with knowledge. Here are answers to some common questions:

Q1: What if a single limit switch fails? A: In an emergency, access the manual operation interface. Select the failed side and set a single-stroke running time to maintain temporary production. Be sure to inspect and repair it promptly during the next shutdown.

Q2: What causes poor spray atomization? A: This is usually due to a clogged nozzle. Replace it with a spare nozzle immediately to resume production, then clean or repair the clogged nozzle.

Q3: Which spare parts should we keep on hand? A: Nozzles, drag chains, limit switches, relays, and air/chemical hoses are common wear parts. We recommend regular inspection and maintaining an inventory of these spares.

Q4: Why is the control cabinet’s green light constantly on? A: Possible reasons include: interlock signal input, motor speed set too low, line fault, or loose chain. Please troubleshoot these possibilities based on your site conditions.

Conclusion: Transform Your Papermaking Process

The journey from “fouling to flawless” in papermaking is no longer an aspiration but an achievable reality with the right partner and technology. Jiangsu Baozhitong Energy Saving Technology Co., Ltd. offers not just a peeling agent spray system, but a comprehensive, intelligent solution designed to eliminate the persistent challenges of machine fouling. Through our patented technology, rigorous design, intelligent automation, and unwavering support, we empower paper manufacturers to achieve unprecedented levels of efficiency, cost reduction, and product quality.

Stop battling fouling reactively and embrace a future of consistent, flawless production.

Ready to transform your papermaking operations and experience the Baozt difference? Contact us today for a customized solution and elevate your productivity.