Unlock Unprecedented Efficiency: How High-Efficiency Spray Systems Reduce Cleaning Downtime by 50%+ in Paper Mills

In the demanding world of papermaking, every minute of operational uptime translates directly into profitability. Yet, a persistent challenge plagues production lines worldwide: the inevitable build-up of contaminants, leading to frequent cleaning cycles and costly downtime. For operations striving to reduce cleaning downtime by 50%+: high-efficiency spray systems emerge not just as an option, but as an essential strategic investment.

This guide will delve into how these advanced systems are revolutionizing the industry, offering a pathway to significantly enhanced productivity and a healthier bottom line.

The Hidden Costs of Cleaning Downtime in Paper Mills

Papermaking is a continuous process, and any interruption can trigger a cascade of negative consequences. When paper machine components, especially dryer cylinders and felts, accumulate stickies, pitch, and other deposits, several critical issues arise:

- Lost Production: Each hour spent cleaning is an hour not producing saleable paper. This direct loss of output significantly impacts revenue.

- Increased Operating Costs: Beyond lost production, frequent cleaning incurs substantial labor costs, chemical expenses, and even energy waste as machinery cools down and restarts.

- Reduced Product Quality: Fouling on surfaces can lead to paper defects, increasing reject rates and impacting customer satisfaction.

- Safety Hazards: Manual cleaning procedures in hot, confined, and often chemically charged environments pose inherent risks to personnel.

- Higher Energy Consumption: Dirty surfaces reduce heat transfer efficiency, forcing machines to consume more steam and energy to maintain desired temperatures.

The cumulative effect of these issues is a significant drag on overall equipment effectiveness (OEE), making proactive solutions vital for modern paper mills.

High-Efficiency Spray Systems: A Game-Changer for Uptime

The core principle behind high-efficiency spray systems is simple yet powerful: to proactively prevent or precisely address contaminant build-up on critical paper machine surfaces. These systems utilize specialized nozzles and intelligent controls to uniformly apply anti-fouling agents, release agents, or cleaning chemicals.

Unlike traditional, reactive cleaning methods, these advanced spray systems work continuously or on demand to maintain surface cleanliness. This shift from reactive to proactive maintenance fundamentally alters the operational paradigm, paving the way for substantial reductions in cleaning-related stoppages.

How High-Efficiency Spray Systems Achieve 50%+ Downtime Reduction

Achieving a significant reduction in cleaning downtime, often exceeding 50%, isn’t magic; it’s the result of combining advanced engineering with intelligent application. Here’s how these systems deliver such impactful results:

- Precision Atomization for Optimal Coverage: The ability to create a fine, uniform mist ensures that the active agents cover surfaces effectively without over-application or waste. This precision maximizes the chemical’s efficacy in preventing adhesion or gently detaching existing deposits.

- Proactive Fouling Prevention: Rather than waiting for deposits to become problematic, continuous or interval spraying forms a protective layer, preventing contaminants from bonding strongly to rollers, felts, and dryer surfaces. This dramatically slows down the rate of build-up.

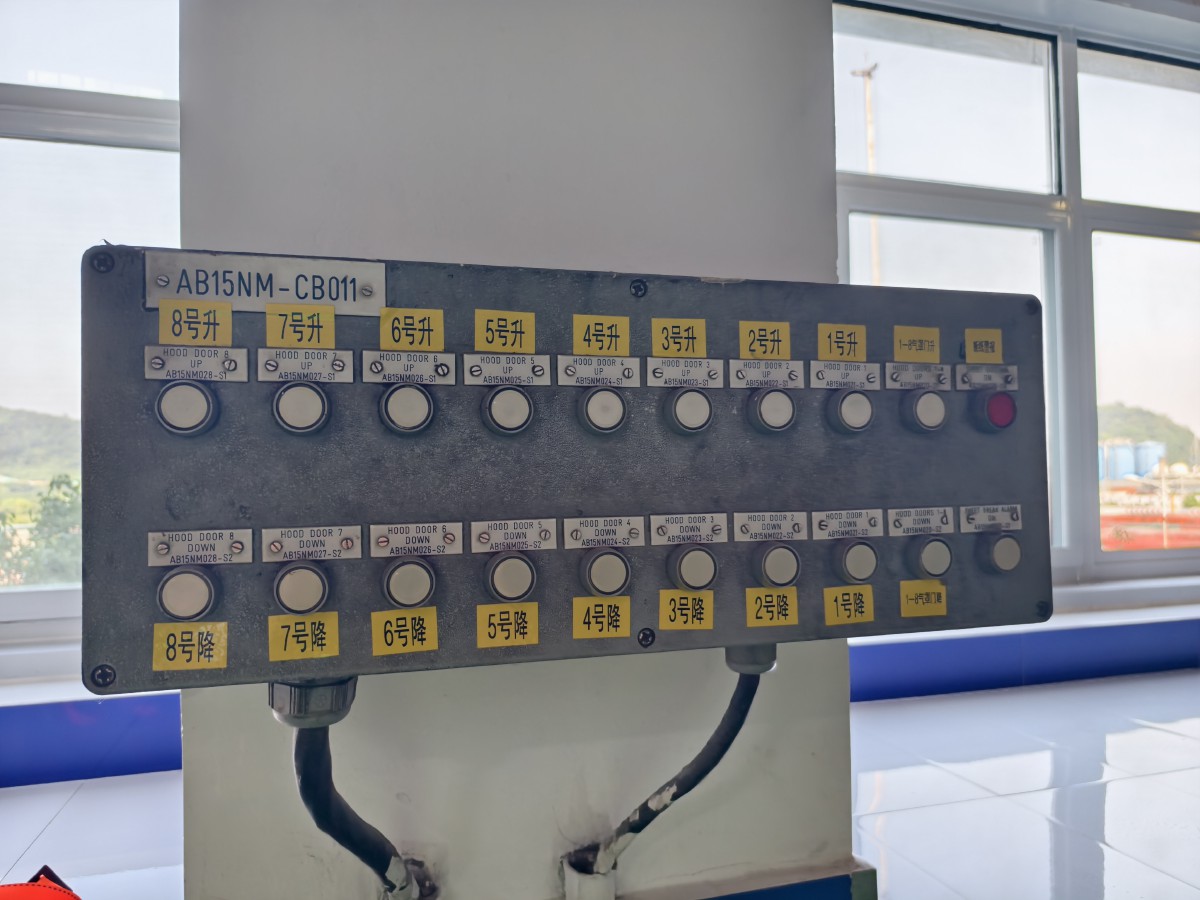

- Automated Operation & Smart Interlocking: Modern spray systems integrate seamlessly with existing production lines. Through PLC-based control and intelligent interlocking with machine signals (like stop/start or sheet breaks), they can operate autonomously, applying agents only when and where needed, optimizing chemical usage and reducing manual intervention.

- Reduced Need for Manual Cleaning: By keeping surfaces cleaner, the frequency and duration of intense manual cleaning cycles are drastically cut. This frees up labor, enhances safety, and minimizes the need for personnel to work in hazardous areas.

- Optimized Energy Utilization: Clean dryer surfaces transfer heat more efficiently. By preventing insulating layers of debris, these systems help maintain optimal heat transfer, directly reducing steam consumption and overall energy costs.

- Rapid Maintenance Design: Systems designed for quick and easy maintenance, often featuring modular components and accessible structures, mean that any necessary servicing can be performed rapidly, further contributing to minimal downtime.

Key Features to Look For in an Advanced Spray System

When evaluating high-efficiency spray systems, look for technologies that prioritize:

- Durability and Material Compatibility: Components must withstand the harsh, corrosive, and high-temperature environments of a paper mill.

- Customization and Adaptability: The system should be configurable to the specific machine geometry, paper width, and operational requirements of your facility.

- Intelligent Control: Features like automated sequencing, remote monitoring, and integration with Distributed Control Systems (DCS) are crucial for truly hands-free operation.

- Proven Performance Metrics: Data-backed results demonstrating reductions in fouling, paper breaks, and actual downtime are essential indicators of efficacy.

- Comprehensive Support: A reliable supplier should offer robust installation, training, and ongoing technical support to ensure long-term system performance.

Introducing Baozhitong: Your Partner in Uninterrupted Production

For paper mills committed to achieving significant operational improvements and looking to reduce cleaning downtime by 50%+: high-efficiency spray systems from Jiangsu Baozhitong Energy Saving Technology Co., Ltd. offer a proven, integrated solution. As a high-tech enterprise dedicated to the papermaking industry, Baozhitong focuses on delivering solutions that are rooted in independent R&D, precision application, energy efficiency, and unwavering reliability. Our commitment to “customer trust” has made us the preferred choice for over 70% of domestic paper enterprises.

Why Baozhitong Stands Apart: Engineered for Excellence

Baozhitong’s intelligent release agent spray system is specifically designed to tackle the industry’s most pressing pain points—fouling, frequent stoppages, and escalating energy costs—by leveraging proprietary technology and extensive industry experience.

- Patented Secondary Atomization Nozzle: Our independently developed nozzle ensures an ultra-fine, uniform mist application. A unique “air barrier” design effectively counteracts on-site airflow disturbances, significantly reducing agent waste and ensuring precise, even coating.

- PLC Smart Interlocking for Seamless Automation: The integrated PLC control system intelligently links with your production line’s signals (e.g., machine stops, sheet breaks). This allows for fully automatic start/stop operations and supports DCS remote control, minimizing human intervention and optimizing agent usage.

- Harsh Environment Design, Built to Last: Understanding the rigors of paper mills, our systems feature 304 stainless steel bodies, core pipelines resistant to up to 240°C, and high-temperature limit switches, ensuring stable operation even in the most challenging conditions.

- Tailored “One Factory, One Policy” Solutions: We don’t believe in one-size-fits-all. Each Baozhitong system is custom-designed and engineered to perfectly adapt to your specific on-site conditions and machine configurations, guaranteeing optimal integration and performance.

- Measurable, Verified Results: Our clients consistently report significant gains:

- Dirt Reduction: 75% – 83%

- Production Efficiency Increase: Approximately 15%

- Reduced Cleaning Downtime: Over 50%

- Overall Cost Reduction: ~30%

- Yield Improvement: ~25%

- Paper Quality Enhancement: ~30%

- Expert Team & Unrivaled Track Record: With a team comprising PhDs and Master’s degree holders, and over 60 patents (20+ core patents applied), our technological prowess is unparalleled. Our collaboration with industry leaders like Lee & Man Paper, Nine Dragons Paper, and APP Sinar Mas Group underscores our trusted position and commitment to mutual success.

Realizing Tangible Benefits: Beyond Just Downtime Reduction

Implementing a Baozhitong intelligent spray system delivers far more than just reduced cleaning downtime. It unlocks a host of interconnected benefits that drive overall operational excellence:

- Reduced Paper Breaks and Higher Yield: By maintaining cleaner surfaces, the primary cause of sheet breaks due to sticking or buildup is eliminated, leading to more stable production and increased sellable paper.

- Significant Energy Savings: The improved heat transfer efficiency on clean dryer cylinders directly translates to reduced steam consumption, a major operational cost for paper mills.

- Enhanced Paper Quality: Consistent surface conditions prevent blemishes and defects, contributing to a higher quality end product that meets stringent market demands.

- Safer Working Environment: Automated cleaning reduces the need for manual intervention in hazardous areas, enhancing worker safety.

- Predictable Operations: With fewer unscheduled stops for cleaning, production planning becomes more reliable and efficient.

Frequently Asked Questions (FAQs) About High-Efficiency Spray Systems

Q1: What if a single limit switch fails on the system? A: Advanced systems often include an emergency operating interface. In case of a single limit switch failure, you can typically select the affected side and set a single-stroke running time, allowing temporary production continuity. It is crucial to schedule maintenance during the next available downtime.

Q2: What causes poor atomization from the spray nozzle? A: Poor atomization is commonly due to nozzle clogging from impurities in the agent or mineral deposits. It’s recommended to have spare nozzles for quick replacement to resume production, then clean or repair the clogged nozzle. Regular filtration and chemical compatibility checks are also important.

Q3: Which spare parts are essential to keep on hand? A: For most high-efficiency spray systems, critical wear parts include spray nozzles, drag chains, limit switches, relays, and air/liquid tubes. Regular inspection and maintaining a small stock of these items can prevent extended downtime.

Q4: My control cabinet’s green light remains on; what could be the issue? A: A continuously illuminated green light on a control cabinet can indicate several issues. Common causes include: active interlocking signals from the production line, a motor speed setting that is too low, electrical line faults, or a loose chain drive within the system. A systematic check of these areas is usually required for diagnosis.

Elevate Your Mill’s Performance Today

The transition to high-efficiency spray systems is a strategic move towards a more productive, sustainable, and profitable future for your paper mill. By choosing a solution designed for precision, durability, and intelligent automation, you can effectively reduce cleaning downtime by 50%+: high-efficiency spray systems from Baozhitong represent a significant leap forward in operational excellence.

Don’t let costly downtime erode your profits. Discover how a customized Baozhitong intelligent spray system can revolutionize your production line.

Contact us today to schedule a consultation and receive a tailored solution designed for your unique operational needs.