In countless industrial environments, the persistent chore of manual cleaning drains resources, disrupts production, and poses safety risks. From the relentless scrubbing of machinery to the painstaking removal of stubborn deposits, the costs — both direct and indirect — quickly accumulate. If your operations still rely on outdated manual methods, you’re not just losing time; you’re actively hindering your potential for growth, efficiency, and sustainability.

It’s time for a critical re-evaluation. The question isn’t whether manual cleaning works, but rather, at what cost and to what effect in today’s demanding industrial landscape.

The Hidden Drain: Unpacking the True Costs of Manual Cleaning

Manual cleaning isn’t just about labor hours; it’s a cascade of inefficiencies that impact your bottom line.

- Skyrocketing Labor Costs & Safety Risks: Human intervention means higher wages, benefits, and the inherent risks of working in hazardous industrial environments, especially around hot, moving machinery or corrosive chemicals.

- Inconsistent Results & Subpar Quality: Human error and fatigue lead to inconsistent cleaning quality. Missed spots, uneven application, and varying effort mean that the root problem is rarely fully addressed, leading to recurring issues.

- Protracted Downtime & Lost Productivity: Each manual cleaning cycle requires shutting down production lines, sometimes for extended periods. This planned downtime, coupled with unplanned stops due to inefficient cleaning, directly translates into lost output and missed revenue opportunities.

- Excessive Resource Consumption: Manual processes often involve overuse of cleaning agents, water, and energy. Without precise control, operators tend to overcompensate, leading to waste and increased operational expenses.

- Environmental Concerns: Inefficient use and disposal of cleaning agents contribute to a larger environmental footprint, making it harder to meet increasingly stringent regulatory standards.

These challenges are particularly acute in industries like pulp and paper, where sticky deposits and fouling can rapidly degrade machine performance, leading to frequent paper breaks and reduced product quality.

The Dawn of Automation: Why Modern Industrial Operations Demand an Automatic Spray System

The answer to these pervasive problems lies in intelligent automation. Upgrading to an automatic spray system is not merely a convenience; it’s a strategic investment in the future of your operations.

Automatic spray systems offer a paradigm shift: they replace the variability and cost of manual intervention with precision, consistency, and relentless efficiency. They operate tirelessly, applying cleaning or treatment agents exactly where and when needed, eliminating waste and maximizing effectiveness. This technological leap allows businesses to reclaim lost production time, drastically reduce operational costs, and elevate product quality to new heights.

Transforming Your Operations: Key Advantages of an Automatic Spray System

Embracing automation unlocks a multitude of benefits that directly address the limitations of manual cleaning:

- Significant Reduction in Downtime: By performing cleaning or treatment tasks rapidly and often in conjunction with minimal line stops, automatic systems drastically cut down on planned and unplanned downtime.

- Unmatched Consistency & Quality: Programmed for precision, these systems ensure every application is identical, leading to superior and predictable results every single time. This consistency translates directly into improved product quality and fewer defects.

- Optimized Resource Consumption: Intelligent controls dispense precise amounts of agents, eliminating guesswork and waste. This leads to substantial savings in chemicals, water, and energy.

- Enhanced Safety Environment: Removing human operators from hazardous cleaning tasks significantly reduces workplace accidents and exposure to harmful substances.

- Increased Productivity & Throughput: With less downtime and more efficient processes, production lines can run longer and more smoothly, boosting overall output and operational efficiency.

- Data-Driven Performance: Modern automatic systems often include monitoring and reporting features, providing valuable data for process optimization and regulatory compliance.

Beyond Basic Cleaning: Introducing the Baozt Intelligent Stripping Agent Spray System

While the general benefits of an automatic spray system are clear, for industries facing specific, complex challenges like those in paper manufacturing, a specialized, high-performance solution is essential. This is where the Jiangsu Baozhitong Energy Saving Technology Co., Ltd. (Baozt) Intelligent Stripping Agent Spray System excels.

Baozt, a leading high-tech enterprise with a profound understanding of the paper industry, has engineered an integrated solution designed to tackle the most stubborn challenges: paper machine fouling. Our system doesn’t just clean; it proactively protects, optimizes, and sustains your production line. As the integrated solution provider for stripping agent spray systems in paper making, Baozt prioritizes “customer trust” as our foundation, driven by independent R&D, precise spraying, energy saving, and stable reliability. We’re proud to serve over 70% of domestic paper enterprises.

Solving Paper Industry Pain Points: The Core of Baozt’s Mission

The increasing demands for environmental protection and water conservation have led to more closed-loop white water systems, exacerbating paper machine fouling. This widespread issue directly impacts production efficiency and product quality. The Baozt Intelligent Stripping Agent Spray System is engineered to resolve this by:

- Utilizing high-precision atomization to apply a uniform protective coating of stripping agent on dryer cylinders or wire meshes.

- Effectively dissolving and peeling off existing contaminants.

- Preventing new pollutants from adhering, tackling the problem at its source.

The results are transformative:

- Eliminates Paper Breaks: Significantly reduces the frequency of paper breaks caused by dirt accumulation, directly boosting finished product yield.

- Drastically Reduces Downtime for Cleaning: Slashes unplanned shutdowns for cleaning, cutting labor and material costs, and maximizing Overall Equipment Effectiveness (OEE).

- Lowers Operational Energy Consumption: A cleaner roller surface ensures higher heat transfer efficiency, reducing steam consumption. Reduced equipment load also contributes to overall energy savings.

Key Impact Data:

- Dirt Reduction Rate: 75% – 83%

- Production Efficiency Increase: Approximately 15%

- Cleaning Downtime Reduction: Over 50%

Baozt’s Six Pillars of Performance: Engineered for Excellence

Our system provides an efficient, intelligent, and reliable stripping agent spray solution, distinguished by six core advantages:

- Efficient & Stable (Significant Enhancement): With a dirt reduction rate exceeding 75%, our system dramatically reduces paper breaks and downtime, leading to a comprehensive increase in production efficiency.

- Precise Spraying (Professional Technology): Our patented secondary atomization nozzles create finer, denser mist droplets for extremely precise and uniform coating. A unique “air barrier” design effectively resists ambient airflow interference, minimizing agent splash and waste.

- Smart Operation (Automatic Control): Integrated PLC intelligent control system automatically interlocks with production line signals (e.g., shutdown, paper breaks) and supports DCS remote start/stop, enabling unmanned, intelligent operation.

- Easy Maintenance (User-Friendly): Innovative structural design allows the main equipment body to be easily pulled out from its tray for convenient inspection. Daily operation requires no manual intervention, and a new automatic fixed-point cleaning function is included.

- Durable Design (Rigorous Engineering): The machine body is constructed from 304 stainless steel, and core pipelines are temperature-resistant up to 240°C. Critical components like limit switches are high-temperature rated, ensuring stable operation even in harsh environments.

- Service Assurance (Worry-Free After-Sales): We provide professional on-site installation guidance, detailed maintenance manuals, and readily available remote technical support and on-site assistance, ensuring peace of mind for our customers.

Under the Hood: How Baozt’s System Delivers Unmatched Results

The Baozt spray system is a sophisticated integration of mechanical, electrical, and automation technologies, built with robust components:

- Equipment Casing & Main Body: Provides protection and support; the main body is the core actuator driving the spray head’s reciprocal motion.

- Pump Station: Features an imported metering pump and flow calibration column, precisely supplying the required flow and pressure of the atomized stripping agent.

- Air Source: Utilizes existing factory compressed air to provide stable power for agent atomization.

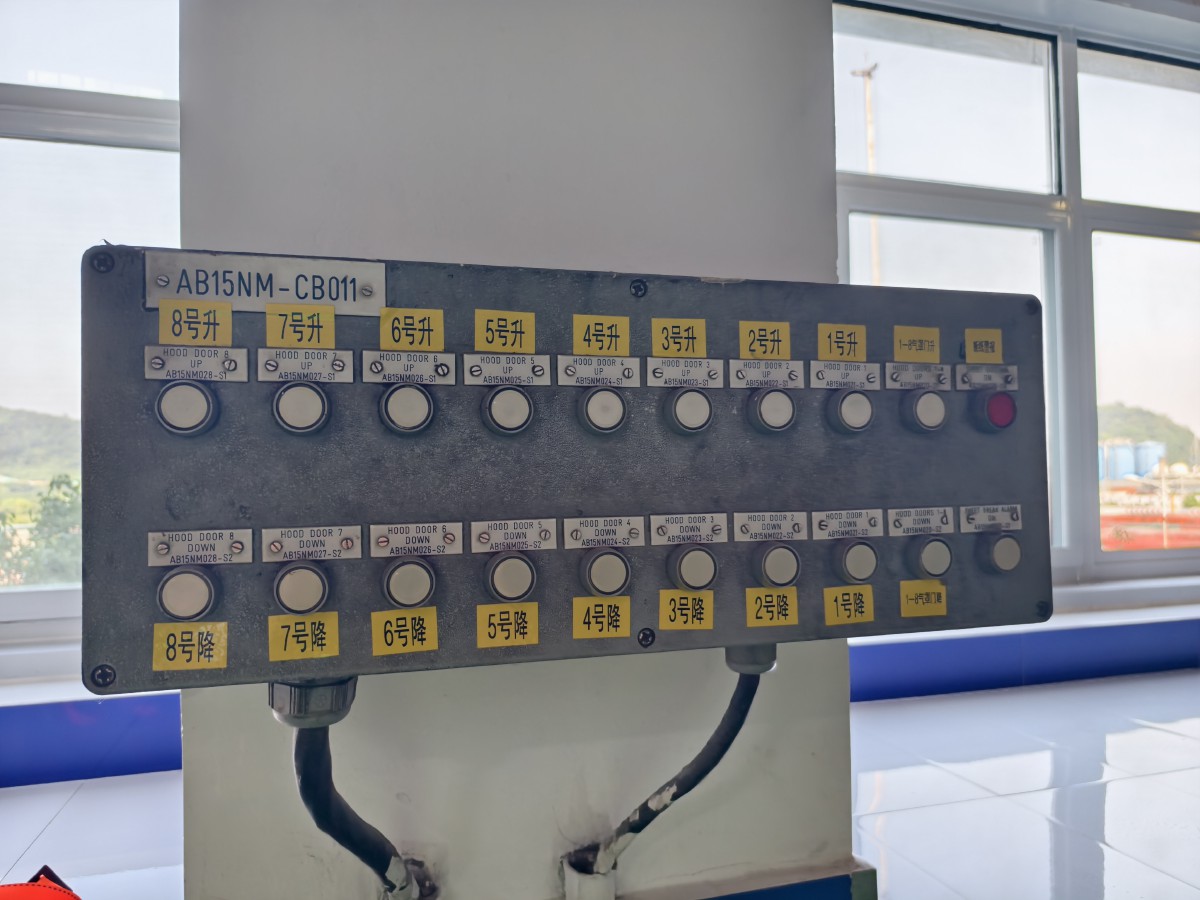

- Control Cabinet: The “brain” of the system, responsible for power, controlling spray head movement patterns and speed, metering pump start/stop, and providing a DCS remote interface.

- Air/Liquid Pipelines: All made from high-temperature resistant (up to 240°C) Teflon, ensuring stable and safe media transport.

- Installation Bracket: Custom-designed based on site conditions (wire or dryer section) to securely mount the main equipment on the production line.

Core Components for Unwavering Performance:

- Patented Secondary Atomization Nozzle: Precision internal structure for ultimate atomization and uniform coverage.

- Imported Japanese Motor: Powerful, resistant to high temperatures and humidity, ensuring stable equipment operation.

- Imported Electromagnetic Metering Pump: Precisely adjustable flow for accurate control over agent consumption.

- High-Temperature Limit Switch: Guarantees stable operation in humid, high-temperature, and harsh conditions.

Intelligent Functions for True Automation:

Our system integrates six advanced intelligent functions for fully automated operation:

- Precise Dynamic Execution: Stepless speed adjustment via frequency converter and movable limit switches enable precise fine-tuning of spraying speed and range.

- High-Efficiency Energy Strategy: Intelligent interlocking design ensures the metering pump stops synchronously when the main machine stops or the system pauses, preventing waste.

- Modular Task Spray Heads: Adjustable nozzle direction, supporting single/double/triple head configurations to flexibly adapt to different paper widths.

- Autonomous Decision Interlocking: Interlocks with production line stop and paper break signals, automatically executing start/stop commands for unattended operation.

- Smart State Sensing: Real-time monitoring of motor and spray head travel, with built-in timeout protection logic for automatic shutdown in case of anomalies.

- Collaborative Control Network: Seamless integration with DCS systems supports remote control and status monitoring, becoming part of your factory’s intelligent production network.

Real-World Impact: The Baozt Difference in Numbers

Baozt’s dedication to innovation is reflected in tangible results and robust market acceptance. Our “Adjustable Range Spraying Device” precisely matches varying paper widths, eliminating waste, while our “Automatic Reversing Spraying Device” ensures exceptional reliability. These innovations are backed by multiple national utility model and invention patents.

We are certified with NQA ISO9001:2015 Quality Management System and recognized as a National High-Tech Enterprise, underscoring our commitment to quality and technological leadership.

Customer Application Results Data:

- Cost Reduction: Approximately 30%

- Yield Increase: Approximately 25%

- Paper Quality Improvement: Approximately 30%

Trusted by Industry Leaders

Jiangsu Baozhitong has forged long-term, stable, and mutually beneficial partnerships with numerous top-tier paper groups in China, including:

- Lee & Man Paper

- Nine Dragons Paper

- Shanying International

- Sinar Mas Group (APP)

- Sun Paper

- Bohui Paper

- Gold Hongye Paper

- Golden Phoenix Paper

- Jianhui Paper

- Rong Sheng Environment

- Hupo Paper

- Solenis (chemical partner)

- And many more industry-leading enterprises like Yuantong Paper, Rongsheng Paper, Shunyu Paper, Huayu Paper.

Choosing Your Upgrade Partner: Why Baozt Stands Out

Our five-year journey, marked by continuous innovation and accumulation, has solidified our position as a leader. From our founding in Suzhou in 2013, focusing on energy-saving and automation, to becoming a National High-Tech Enterprise in 2020, and achieving 60 patents (20+ core patents) by 2023, Baozt embodies expertise and reliability. Our team of 40+ professionals, including 2 PhDs and 4 Master’s degree holders, with over 50% technical staff, ensures we remain at the forefront of technological advancement.

Frequently Asked Questions (FAQs) About Your Automatic Spray System Upgrade

We understand you might have questions about transitioning to an automated system. Here are answers to some common concerns:

Q1: What if a single limit switch fails?

A: In case of a single limit switch failure, you can access the emergency operation interface. Select the failed side and set a single-stroke running time to ensure temporary production continuity. It is crucial to perform maintenance or repair the switch as soon as the line stops.

Q2: What if the spray head’s atomization effect is poor?

A: Poor atomization is typically caused by a clogged spray head. Please replace it with a spare spray head immediately to restore production. Afterwards, you can repair or clean the clogged spray head.

Q3: Which parts should I keep as common spare parts?

A: Spray heads, drag chains, limit switches, relays, and air/chemical tubes are common wear parts. We recommend regular inspection and keeping a supply of these spare parts on hand.

Q4: Why is the control cabinet’s green light constantly on?

A: A continuously illuminated green light on the control cabinet can indicate several issues: a persistent interlocking signal input, the motor speed being set too low, a circuit fault, or a loose chain. Please check these possibilities one by one based on your specific site conditions.

The Future of Industrial Cleaning is Automated

The era of costly, inconsistent, and hazardous manual cleaning is over. The competitive landscape demands higher efficiency, greater consistency, and unwavering reliability. Upgrading to an automatic spray system is not just an option; it’s a necessity for any forward-thinking industrial operation. The Baozt Intelligent Stripping Agent Spray System represents the pinnacle of this evolution, offering a proven, precise, and powerful solution specifically tailored for the demanding environment of paper manufacturing.

Ready to Revolutionize Your Operations?

Don’t let manual cleaning hold you back. Discover how the Baozt Intelligent Stripping Agent Spray System can transform your production line, enhance your product quality, and significantly boost your profitability.

Contact Jiangsu Baozhitong Energy Saving Technology Co., Ltd. today for a customized solution and witness the power of automation.